What is RTLS: Benefits, Use Cases, and How It Works

Real-Time Location Systems provide continuous, sub-meter accurate positioning of assets, personnel, and equipment across complex indoor environments, enabling data-driven operational optimization, enhanced safety protocols, and measurable business improvements through advanced positioning technologies and intelligent analytics.

Contact Us

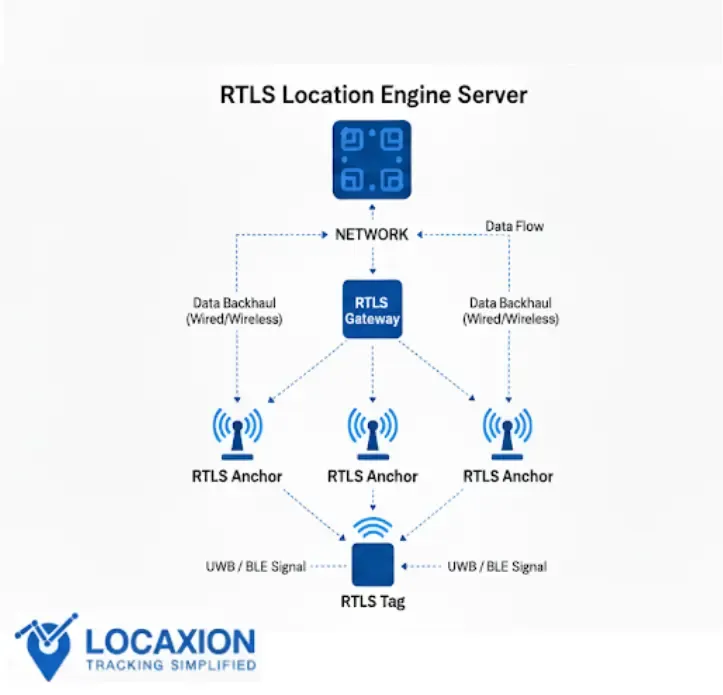

What is Real-Time Location Systems (RTLS) Technology

RTLS serves as the central nervous system for modern operations, delivering continuous visibility into every asset, person, and process with sub-meter accuracy through advanced positioning technologies, enabling data-driven decision making and operational excellence across complex industrial environments.

RTLS Tags & Transmitters

Compact wireless devices that broadcast location signals with multi-year battery life and industrial durability

RTLS Anchors & Receivers

Fixed infrastructure that receives tag signals and provides precise positioning reference points

RTLS Location Engine

Intelligent software that processes signals into accurate position data with real-time analytics

How RTLS Position Calculation Technology Works

Understanding advanced localization techniques and the science behind position calculation helps you select the right technology and optimize performance for your specific requirements and operational environments.

Time Difference of Arrival (TDoA)

Measures time differences between signals reaching multiple receivers

Angle of Arrival (AoA)

Determines position based on signal arrival angles at receivers

Time of Flight (ToF) in RTLS

Calculates distance based on signal travel time

Two-Way Ranging (TWR)

Bidirectional ranging for enhanced accuracy

Received Signal Strength (RSSI)

Position estimation based on signal strength measurements

Simultaneous Localization and Mapping (SLAM)

Builds maps of unknown environments while simultaneously tracking location within those maps

Comprehensive RTLS Technology Comparison Guide

Select the optimal positioning technology based on your specific accuracy requirements, operational range needs, environmental constraints, and cost considerations through detailed comparison of leading RTLS technologies and their real-world performance characteristics.

Ultra-Wideband (UWB)

- Highest accuracy

- Immune to multipath

- Low interference

Bluetooth Low Energy (BLE)

- Cost-effective

- Wide device support

- Easy deployment

Wi-Fi Based RTLS

- Existing infrastructure

- Good coverage

- Moderate accuracy

SLAM-Based RTLS

- Indoor & outdoor coverage

- Wall penetration

- Sub-meter accuracy

Ultrasound RTLS

- High accuracy

- Short range

- Indoor only

Chirp Spread Spectrum (CSS) RTLS

- Long range

- Low power

- Penetrates obstacles

RTLS Technology Selection Framework

Choose the right RTLS technology based on your specific requirements using this comprehensive comparison matrix that evaluates accuracy, range, cost, and environmental suitability across all major positioning technologies.

| Technology | Accuracy | Range | Battery Life | Cost | Best For |

|---|---|---|---|---|---|

| Ultra-Wideband (UWB) | 10–30cm | 200m | 2–5 years | $$$$ | High-precision applications |

| Bluetooth Low Energy | 1–5m | 50m | 2–5 years | $$ | Cost-effective deployments |

| Wi-Fi Based | 3–15m | 100–150m | 5–10 hours | $$$ | Existing infrastructure |

| SLAM | 10–50cm | Variable | 1–2 hours | $$$$ | Mobile platforms |

| Ultrasound | 1–10cm | 10–30m | 2–5 years | $$$ | Long accuracy, short range |

| Chirp Spread Spectrum | 1–1.5m | 100–300m | 5–10 years | $$ | Long range, low cost |

RTLS Applications Across Industries and Operational Environments

Discover how Real-Time Location Systems transform operations across manufacturing, healthcare, logistics, and specialized industries through measurable business outcomes, enhanced safety protocols, and data-driven operational optimization tailored to specific industry requirements and regulatory compliance needs.

Manufacturing & Warehousing

Optimize production workflows, track work-in-progress, and enhance worker safety.

- Asset utilization

- Process optimization

- Worker safety

Healthcare

Improve patient safety, track medical equipment, and optimize staff workflows.

- Patient care

- Equipment utilization

- Staff efficiency

Logistics & Supply Chain

Enhance supply chain visibility, streamline warehouse operations, and improve delivery accuracy.

- Supply chain visibility

- Warehouse optimization

- Delivery accuracy

Quantifiable RTLS Benefits and Measurable Business Impact

RTLS delivers measurable improvements across operational efficiency, safety compliance, and financial performance with verified industry data and documented case studies demonstrating substantial return on investment and sustained competitive advantages through data-driven operational optimization.

Operational Efficiency Gains

Measurable improvements in asset utilization, process optimization, and productivity

Key Metrics:

- 25–40% asset utilization increase

- 15–30% productivity improvement

- 70–90% search time reduction

Enhanced Safety & Compliance

Improved workplace safety through real-time monitoring and automated compliance reporting

Key Metrics:

- 60–80% safety incident reduction

- 95%+ compliance accuracy

- 50–70% faster emergency response

Financial Performance Impact

Quantifiable ROI through cost reduction, revenue optimization, and risk mitigation

Key Metrics:

- 150–300% ROI within 18 months

- 20–35% operational cost reduction

- 10–25% revenue increase

RTLS ROI Calculator Framework

Calculate your potential return on investment using industry-verified metrics and proven methodologies for RTLS implementation across different operational scenarios and business environments.

Cost Savings

- Labor efficiency gains

- Asset utilization improvement

- Search time elimination

- Maintenance optimization

Revenue Enhancement

- Throughput increase

- Quality improvements

- Customer satisfaction

- Compliance benefits

Risk Mitigation

- Safety incident reduction

- Asset loss prevention

- Compliance automation

- Insurance benefits

Implementation Costs

- Hardware investment

- Software licensing

- Installation services

- Training and support

Systematic RTLS Implementation Guide and Best Practices

Follow proven methodologies and best practices for successful RTLS deployment through systematic approach to assessment, design, implementation, and optimization that ensures optimal performance, user adoption, and sustained value realization across complex operational environments.

Assessment & Planning

Comprehensive site survey, requirements analysis, and technology selection based on operational needs.

Infrastructure Design

Network architecture design, anchor placement optimization, and coverage planning for optimal performance.

Pilot Deployment

Limited-scope testing, performance validation, and process refinement before full rollout.

Full-Scale Rollout

Phased deployment across all operational areas with comprehensive training and support.

Optimization & Support

Continuous monitoring, performance optimization, and ongoing support for sustained value realization.

Real-World RTLS Applications and Implementation Examples

Explore specific use cases and implementation examples across different industries and environments, demonstrating proven RTLS solutions that deliver measurable business outcomes and operational improvements through targeted applications and industry-specific optimizations.

Forklift Tracking & Safety

Real-time forklift monitoring with collision avoidance and operator safety

- 40% reduction in accidents

- 25% improvement in efficiency

- Real-time fleet optimization

Medical Equipment Tracking

Automated tracking of critical medical equipment and assets

- 95% equipment availability

- 60% reduction in search time

- Improved patient care

Yard Management System

Comprehensive tracking of trailers, containers, and yard operations

- 50% faster dock operations

- 30% improvement in yard utilization

- Real-time visibility

Worker Safety Monitoring

Real-time worker location and safety monitoring with emergency alerts

- 80% reduction in safety incidents

- Faster emergency response

- Compliance automation

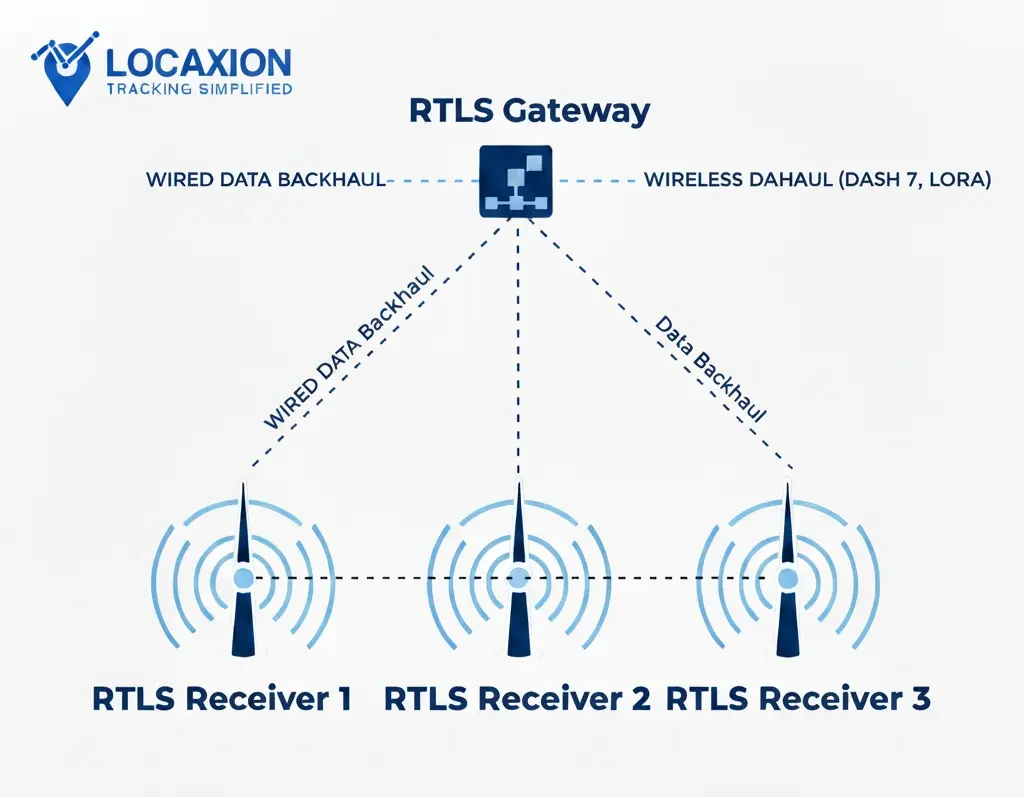

Anchors & Receivers Infrastructure

RTLS Infrastructure Fundamentals

RTLS anchors and receivers form the critical infrastructure backbone that captures tag signals and enables precise positioning calculations. These strategically positioned devices create a comprehensive coverage network with overlapping zones for continuous tracking accuracy.

Infrastructure Components

Fixed Anchors

Permanently mounted reference points providing stable positioning coordinates with known locations.

Mobile Receivers

Portable units for temporary coverage areas and flexible deployment scenarios.

Gateway Nodes

Network bridges connecting anchor infrastructure to central processing systems.

Sync Masters

Timing coordination devices ensuring synchronized signal processing across the network.

Technical Specifications

Advanced Capabilities

- Multi-frequency operation support

- Automatic network self-healing

- Dynamic power optimization

- Interference detection and mitigation

- Remote configuration and monitoring

- Redundant positioning calculations

- Edge processing capabilities

- Scalable mesh networking

Deployment Planning Considerations

Coverage Design

- Minimum 4 anchors per zone

- 20–30% overlap between zones

- Line-of-sight optimization

- Height and mounting considerations

Network Architecture

- Ethernet backbone connectivity

- Power over Ethernet (PoE+)

- Redundant communication paths

- Central processing integration

Environmental Factors

- RF interference assessment

- Physical obstruction mapping

- Temperature and humidity ranges

- Maintenance accessibility

Plan Your RTLS Infrastructure

Get expert site survey and infrastructure design services for optimal RTLS deployment.

Tags & Transmitters Technology

RTLS Tag Technology Fundamental

RTLS tags are sophisticated wireless devices that combine advanced radio frequency transmission, intelligent power management, and multi-sensor capabilities to provide continuous, real-time location and status information with sub-meter accuracy across industrial environments.

Tag Categories & Applications

Asset Tags

Rugged, industrial-grade tags for equipment, tools, and high-value inventory tracking with tamper detection

Personnel Tags

Wearable safety badges with duress buttons, man-down detection, and zone-based alerts

Vehicle Tags

Heavy-duty tags for forklifts, AGVs, and mobile equipment with motion sensors

Environmental Tags

Specialized tags with temperature, humidity, and shock sensors for sensitive assets

Technical Specifications

Advanced Capabilities

- Configurable transmission intervals

- Multi-year battery life optimization

- Environmental sensors integration

- Tamper detection and alerts

- Industrial-grade durability

- Encrypted data transmission

- Low-power sleep modes

- Over-the-air configuration

Deployment Planning Considerations

Environment Factors

- Temperature extremes

- Moisture and chemical exposure

- Physical impact resistance

- RF interference levels

Performance Requirements

- Update frequency needs

- Battery life expectations

- Accuracy requirements

- Range and coverage

Integration Needs

- Sensor data requirements

- Alert and notification needs

- System integration complexity

- Scalability requirements

Ready to Deploy RTLS Tags?

Discover how our advanced tag technology can transform your operations with precise location intelligence.

Physical Assets: The Foundation of Digital Twin Technology

Physical Assets Technology Fundamentals

Physical assets form the foundation of Digital Twin implementations through intelligent sensor integration, real-time data generation, and continuous monitoring capabilities that enable accurate virtual representations of real-world objects, systems, and processes across complex operational environments.

Physical Asset Categories

Manufacturing Equipment

CNC machines, robotic systems, assembly lines, and production equipment with integrated sensors

Infrastructure Systems

Buildings, HVAC systems, power distribution, and facility management infrastructure

Transportation Assets

Vehicles, aircraft, ships, and logistics equipment with telematics and tracking systems

Energy Systems

Power generation, renewable energy systems, smart grids, and energy distribution networks

Technical Specifications

Key Advantages

- Real-time performance monitoring

- Predictive maintenance capabilities

- Operational efficiency optimization

- Remote asset management

- Condition-based maintenance

- Asset lifecycle tracking

- Performance benchmarking

- Automated alert systems

Sensor Integration Technologies

Environmental Sensors

- Temperature and humidity monitoring

- Pressure and flow measurement

- Air quality and emissions tracking

- Noise and vibration analysis

Performance Sensors

- Speed and acceleration tracking

- Power consumption monitoring

- Efficiency and throughput metrics

- Quality and defect detection

Condition Monitoring

- Wear and tear assessment

- Lubrication and fluid levels

- Structural health monitoring

- Predictive failure indicators

Optimize Physical Asset Performance

Transform your physical assets into intelligent, connected systems with comprehensive Digital Twin integration.

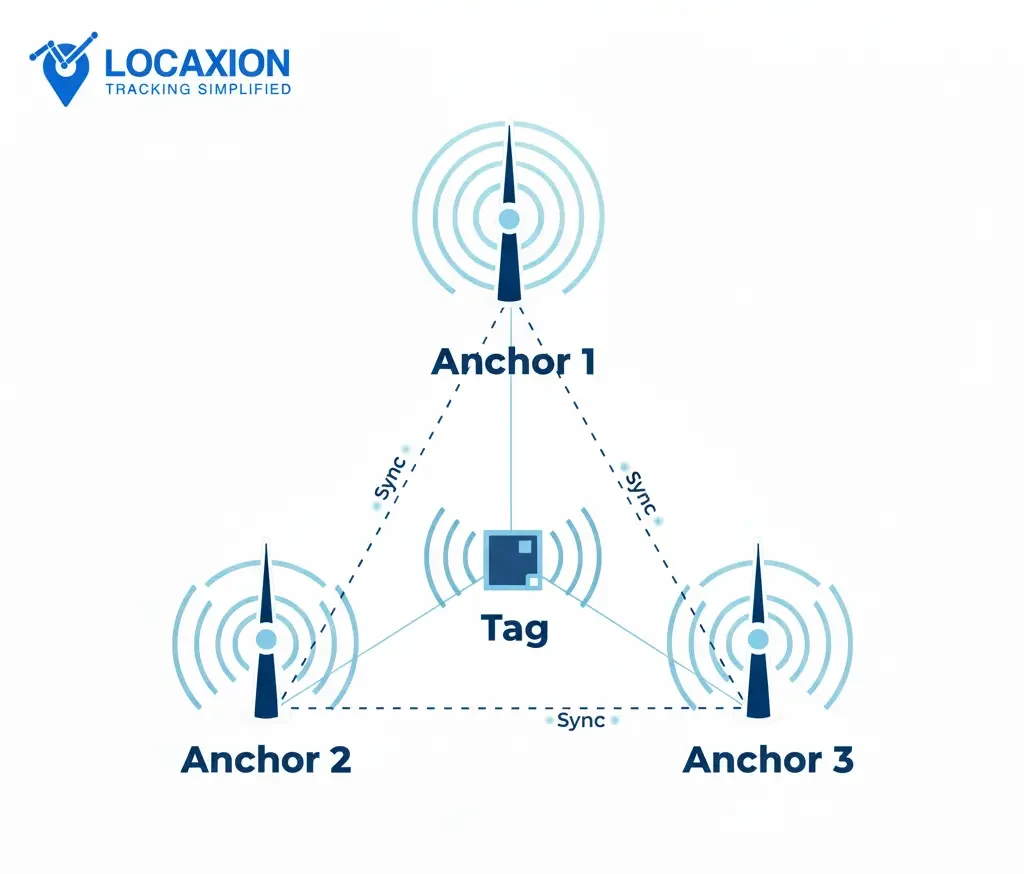

Time Difference of Arrival (TDoA) Algorithm

TDoA Positioning Algorithm Fundamentals

Time Difference of Arrival (TDoA) calculates position by measuring the time differences between a signal reaching multiple synchronized receivers, eliminating the need for precise tag timing while maintaining high accuracy through advanced mathematical algorithms and hyperbolic positioning techniques.

TDoA Method Categories

Uplink TDoA

Tag transmits to multiple synchronized receivers, eliminating tag clock requirements

Downlink TDoA

Multiple synchronized transmitters send to tag, enabling mobile device positioning

Hybrid TDoA

Combines uplink and downlink for enhanced accuracy and redundancy

Multi-Frequency TDoA

Uses multiple frequency bands to improve accuracy and reduce multipath effects

Technical Specifications

Key Advantages

- No tag synchronization required

- High accuracy with proper infrastructure

- Scalable to large areas

- Works with simple tag designs

- Robust against clock drift

- Supports high update rates

- Excellent for asset tracking

- Proven in industrial environments

Mathematical Foundation

Hyperbolic Equations

- Time difference measurements

- Hyperbola intersection calculations

- Least squares optimization

- Error minimization algorithms

Synchronization Methods

- GPS-based time reference

- Wired synchronization networks

- Over-the-air sync protocols

- Crystal oscillator stability

Error Sources

- Multipath propagation

- Clock synchronization drift

- Non-line-of-sight conditions

- Environmental interference

Implement TDoA Positioning

Leverage TDoA algorithms for high-accuracy positioning in your RTLS deployment.

Angle of Arrival (AoA) Algorithm

AoA Positioning Technology Fundamentals

Angle of Arrival (AoA) positioning determines location by measuring the angle at which signals arrive at receivers using sophisticated antenna arrays and signal processing algorithms, providing directional information that enables triangulation-based position calculation with minimal infrastructure requirements.

AoA Implementation Methods

Phased Array Systems

Multiple antenna elements with controlled phase relationships for precise angle measurement

Switched Beam Arrays

Directional antennas switched sequentially to determine signal arrival direction

Interferometry

Phase difference analysis between antenna elements for high-precision angle detection

MIMO Processing

Multiple-input multiple-output systems for enhanced angular resolution and accuracy

Technical Specifications

Key Advantages

- Minimal infrastructure requirements

- No time synchronization needed

- Works with simple tags

- Good for directional tracking

- Scalable coverage areas

- Robust signal processing

- Cost-effective deployment

- Suitable for outdoor applications

Signal Processing Techniques

Beamforming Algorithms

- Conventional beamforming

- Adaptive beamforming

- MUSIC algorithm

- ESPRIT method

Antenna Configurations

- Linear antenna arrays

- Circular antenna arrays

- Planar antenna arrays

- Conformal antenna arrays

Calibration Methods

- Phase calibration procedures

- Amplitude matching

- Environmental compensation

- Real-time adjustments

Deploy AoA Technology

Explore how Angle of Arrival positioning can optimize your location tracking requirements.

Time of Flight (ToF) Measurement Technology

ToF Direct Distance Measurement Fundamentals

Time of Flight (ToF) positioning measures the round-trip time of radio signals between tags and anchors to calculate direct distances with high precision, providing reliable positioning through actual signal propagation time measurement and robust performance in challenging RF environments.

ToF Implementation Methods

UWB Pulse-Based ToF

Ultra-wideband short pulse transmission with precise time-of-arrival detection

Chirp Spread Spectrum

Continuous wave frequency modulation with correlation-based distance measurement

Phase-Based Measurement

Carrier phase analysis for high-resolution distance determination

Leading Edge Detection

First path signal detection algorithms for multipath mitigation

Technical Specifications

Key Advantages

- Direct distance measurement

- High accuracy in line-of-sight

- Robust signal processing

- Works with various radio technologies

- Excellent for precision applications

- Scalable deployment options

- Environmental compensation capable

- Real-time positioning updates

Implementation Considerations

Signal Processing

- High-resolution time measurement

- Multipath mitigation algorithms

- Environmental compensation

- Noise filtering and smoothing

Hardware Requirements

- Precise timing circuits

- High-speed signal processing

- Temperature-stable oscillators

- Advanced RF front-ends

Deployment Factors

- Line-of-sight requirements

- Anchor placement optimization

- Environmental calibration

- System synchronization needs

Ready to Deploy RTLS Tags?

Discover how our advanced tag technology can transform your operations with precise location intelligence.

Two-Way Ranging (TWR) Protocol Technology

TWR Synchronized Ranging Fundamentals

Two-Way Ranging (TWR) eliminates clock synchronization requirements by measuring round-trip signal propagation time between devices, providing highly accurate distance measurements through bidirectional communication that automatically compensates for clock offsets and processing delays.

TWR Protocol Types

Single-Sided TWR (SS-TWR)

Basic two-message exchange with simple round-trip time calculation

Double-Sided TWR (DS-TWR)

Enhanced three-message protocol with improved clock drift compensation

Symmetric DS-TWR (SDS-TWR)

Optimized protocol with symmetric timing for maximum accuracy

Alternative DS-TWR (ADS-TWR)

Modified protocol for specific deployment scenarios and requirements

Technical Specifications

Key Advantages

- No infrastructure synchronization

- Automatic clock drift compensation

- High accuracy measurements

- Simplified deployment process

- Robust against timing errors

- Scalable to many tags

- Works with various technologies

- Reduced maintenance overhead

Protocol Implementation

Message Exchange

- Poll message transmission

- Response message acknowledgment

- Final message with timestamps

- Distance calculation algorithms

Technology Platforms

- UWB-based TWR systems

- Bluetooth ranging protocols

- Wi-Fi RTT implementations

- Proprietary radio solutions

Error Sources

- Processing delay variations

- Clock frequency differences

- Multipath propagation effects

- Environmental interference

Simplified TWR Deployment

Eliminate synchronization complexity with Two-Way Ranging protocols for your RTLS system.

Received Signal Strength (RSSI) - Signal Power-Based Positioning

RSSI Positioning Technology Fundamentals

Received Signal Strength Indicator (RSSI) positioning leverages signal power measurements to estimate distances and determine location through cost-effective radio infrastructure, providing reasonable accuracy for applications where broad coverage and low deployment costs are prioritized over precision.

RSSI Method Categories

Fingerprinting Method

Pre-calibrated signal strength maps for location matching and pattern recognition

Trilateration Method

Distance estimation using path loss models and geometric positioning calculations

Proximity Detection

Zone-based tracking using signal strength thresholds and presence detection

AMachine Learning

AI-enhanced positioning using neural networks and adaptive signal processing

Technical Specifications

Advanced Features

- Existing infrastructure utilization

- Environmental calibration

- Mobile device integration

- Zone-based notifications

- Machine learning enhancement

- Multi-technology fusion

- Real-time signal filtering

- Scalable deployment

RSSI Selection Criteria

Environment Factors

- Signal propagation characteristics

- Multipath and interference levels

- Physical obstruction density

- Environmental stability

- Existing infrastructure availability

Performance Requirements

- Accuracy tolerance levels

- Update frequency needs

- Coverage area requirements

- Battery life expectations

- Cost constraints

Integration Needs

- Existing system compatibility

- Mobile device integration

- Cloud platform requirements

- Scalability considerations

- Maintenance capabilities

Cost-Effective RSSI Solutions

Leverage existing infrastructure for proximity-based location tracking with RSSI technology.

SLAM - Autonomous Mapping and Positioning Technology

SLAM Technology Fundamentals

Simultaneous Localization and Mapping (SLAM) creates detailed maps of unknown environments while simultaneously tracking position through advanced sensor fusion, machine learning algorithms, and real-time processing without requiring pre-installed infrastructure.

SLAM Method Categories

LiDAR SLAM

Laser-based 3D mapping with high precision distance measurements and point cloud processing

Visual SLAM (vSLAM)

Camera-based mapping using computer vision and feature detection algorithms

RGB-D SLAM

Combined color and depth sensor mapping for enhanced environmental understanding

Inertial SLAM

IMU-enhanced positioning with motion sensors and accelerometer integration

Technical Specifications

Advanced Features

- Real-time map building

- Multi-sensor fusion

- Probabilistic mapping

- 3D point cloud processing

- Loop closure detection

- Autonomous navigation

- Dynamic environment adaptation

- Machine learning optimization

SLAM Selection Criteria

Environment Factors

- Dynamic vs static environments

- Lighting conditions and visibility

- Structural feature availability

- Space complexity and size

- Obstacle density and patterns

Performance Requirements

- Mapping accuracy needs

- Real-time processing requirements

- Computational resource availability

- Autonomous operation level

- Scalability expectations

Integration Needs

- Robotic platform compatibility

- Sensor suite requirements

- Navigation system integration

- Data processing capabilities

- Maintenance and updates

Autonomous SLAM Solutions

Deploy infrastructure-free positioning with advanced SLAM technology for autonomous operations.

Ultra-Wideband Technology Deep Dive

Ultra-Wideband RTLS Fundamentals

Ultra-Wideband (UWB) technology represents the gold standard in RTLS precision, delivering centimeter-level accuracy through advanced time-of-flight measurements and sophisticated signal processing. UWB systems excel in mission-critical applications requiring the highest positioning accuracy, making them ideal for precision manufacturing, healthcare, and high-value asset tracking where location precision directly impacts operational success and safety outcomes.

Technical Advantages

Exceptional Accuracy

10–30cm positioning precision in real-world conditions with multipath resistance.

Multipath Immunity

Wide bandwidth provides superior resistance to signal reflections and interference.

Low Interference

Spread spectrum technology minimizes RF conflicts with existing systems.

High Update Rates

Real-time tracking with minimal latency for dynamic applications.

Technical Specifications

Key Features

- Centimeter-level positioning accuracy

- Immune to multipath interference

- Low power consumption optimization

- Secure encrypted communication

- Industrial-grade durability (IP67/IP68)

- Real-time location updates

- Scalable network architecture

- Professional deployment support

Ideal Applications & Use Cases

Manufacturing Excellence

- High-value tool and equipment tracking

- Precision assembly line optimization

- Quality control and compliance

- Worker safety in hazardous zones

- Automated guided vehicle navigation

Healthcare-Critical Systems

- Critical medical equipment tracking

- Patient and staff safety monitoring

- Surgical instrument management

- Infection control compliance

- Emergency response optimization

Logistics & Warehousing

- High-volume cargo and inventory tracking

- Automated warehouse operations

- Cold chain monitoring and compliance

- Forklift and vehicle fleet management

- Dock and yard management systems

Explore UWB Solutions & Resources

Technology Comparisons

Deploy Ultra-Wideband RTLS

Experience centimeter-level accuracy with the gold standard in RTLS technology for mission-critical applications.

Bluetooth Low Energy Technology Deep Dive

BLE RTLS Technology Fundamentals

Bluetooth Low Energy (BLE) provides a cost-effective RTLS solution with excellent battery life and widespread device compatibility, making it ideal for applications requiring room-level accuracy and broad deployment across large facilities with moderate positioning requirements.

Technology Benefits

Cost-Effective Deployment

Lower infrastructure and tag costs enable large-scale implementations.

Universal Compatibility

Works with smartphones, tablets, and existing BLE infrastructure.

Extended Battery Life

Ultra-low power consumption extends operational life to 2–5 years.

Rapid Deployment

Simple installation and configuration for quick project rollouts.

Technical Specifications

Core Capabilities

- Room-level positioning accuracy

- Smartphone and tablet integration

- Beacon-based infrastructure

- RSSI and proximity detection

- Mesh networking capabilities

- Over-the-air configuration

- Cloud-based management

- Scalable deployment architecture

Optimal Use Cases & Applications

Healthcare Facilities

- Patient flow optimization

- Staff location and communication

- Infotainment orientation tracking

- Visitor management systems

- Emergency evacuation assistance

Retail & Hospitality

- Customer journey analytics

- Staff productivity monitoring

- Asset and inventory tracking

- Proximity marketing campaigns

- Queue management optimization

Office & Corporate

- Workspace utilization monitoring

- Employee safety monitoring

- Meeting room optimization

- Asset and equipment tracking

- Contact tracing capabilities

Explore BLE Solutions & Resources

Cost-Effective Solutions

Deploy Cost-Effective BLE RTLS

Leverage widespread device compatibility and excellent battery life for large-scale, budget-friendly RTLS deployments.

Wi-Fi Based Technology Deep Dive

Wi-Fi RTLS Technology Fundamentals

Wi-Fi based RTLS leverages existing wireless infrastructure to provide cost-effective location services, utilizing signal strength (RSSI) and time-of-flight measurements for room to zone-level accuracy in environments with established Wi-Fi networks.

Infrastructure Advantages

Existing Infrastructure

Leverage current Wi-Fi access points and network infrastructure.

Wide Coverage Area

Extensive range with good penetration through walls and obstacles.

Dual-Purpose Network

Provides both connectivity and location services simultaneously.

Scalable Architecture

Easily expandable using existing network management tools.

Technical Specifications

System Features

- RSSI-based positioning algorithms

- Time-of-flight measurements

- Triangulation location methods

- Multi-purpose asset integration

- Existing network integration

- Centralized management platform

- Real-time location analytics

- Mobile device compatibility

Ideal Implementation Scenarios

Corporate Environments

- Office space utilization tracking

- Employee location services

- Meeting room optimization

- Visitor management systems

- Emergency evacuation support

Educational Institutions

- Student and staff tracking

- Campus navigation assistance

- Classroom and asset management

- Security and safety monitoring

- Resource utilization analytics

Large Facilities

- Zone-level asset tracking

- Personnel location monitoring

- Facility optimization

- Security access control

- Maintenance scheduling support

Wi-Fi RTLS Solutions & Resources

Wi-Fi Applications

Infrastructure Optimization

Implementation Services

Leverage Existing Wi-Fi Infrastructure

Transform your existing Wi-Fi network into a powerful RTLS system with minimal additional infrastructure investment.

VHF Technology Deep Dive

VHF RTLS Technology Fundamentals

VHF (Very High Frequency) RTLS technology uses low-frequency waves (148–174 MHz) capable of penetrating walls and obstacles, providing reliable indoor and outdoor positioning with sub-meter accuracy using innovative phase measurement algorithms and minimal infrastructure investment.

Technology Advantages

Indoor & Outdoor Coverage

Reliable positioning both inside and outside buildings with wall penetration.

Scalability

Cover 1 square kilometer with just four antennas for unlimited devices.

Precision & Reliability

Sub-meter accuracy with ability to traverse up to 50 meters of concrete.

GNSS Independence

Remains functional during GNSS jamming, spoofing, or unavailability.

Technical Specifications

System Features

- Low-frequency wave transmission

- Phase measurement algorithms

- Direct path signal recognition

- Penetrative accuracy monitoring

- Location precision optimization

- Local data processing capability

- Minimal infrastructure requirements

- Mobile-ready tracking

Ideal Applications & Use Cases

Industry 4.0 & Manufacturing

- Asset tracking across facilities

- Worker safety monitoring

- Equipment location management

- Production workflow optimization

- Quality control processes

Security & Defense

- Personnel tracking in facilities

- Critical site access control

- Emergency response coordination

- Mission-critical operations

- Secure environments

Large-Scale Deployments

- Campus-wide asset tracking

- Underground facilities

- Mixed indoor/outdoor environments

- Industrial-scale monitoring

- Infrastructure resilience

VHF RTLS Solutions & Resources

Industry Solutions

Deploy VHF for Maximum Coverage

Cover 1 square kilometer with just four antennas and achieve sub-meter accuracy with superior wall penetration.

Ultrasound Technology Deep Dive

Ultrasound RTLS Technology Fundamentals

Ultrasound RTLS uses high-frequency sound waves (typically 40–80 kHz) for precise positioning, offering excellent accuracy in controlled indoor environments where line-of-sight can be maintained and environmental conditions are stable, making it ideal for high-precision applications.

Technology Benefits

Exceptional Precision

1–10cm accuracy in optimal conditions with minimal interference.

Cost-Effective Hardware

Simple transducers and receivers keep system costs manageable.

Low RF Interference

Acoustic signals don’t interfere with wireless communications.

Deterministic Performance

Predictable behavior in controlled indoor environments.

Technical Specifications

System Characteristics

- Time-of-flight positioning method

- Line-of-sight requirement

- Temperature compensation algorithms

- Multi-transducer triangulation

- Acoustic signal processing

- Environmental calibration

- Interference rejection filters

- Real-time position calculation

Optimal Applications & Environments

Precision Manufacturing

- High-precision assembly operations

- Quality control and inspection

- Tool and fixture positioning

- Robotic arm guidance systems

- Classroom environment tracking

Laboratory & Research

- Scientific equipment positioning

- Sample and specimen tracking

- Automated laboratory systems

- Research apparatus monitoring

- Controlled environment studies

Specialized Healthcare

- Medical equipment location

- Patient monitoring applications

- Rehabilitation exercise monitoring

- Sterile environment applications

Ultrasound RTLS Solutions & Resources

Precision Applications

Technology Guides

Achieve Centimeter Precision

Deploy ultrasound RTLS for exceptional 1–10cm accuracy in controlled environments with minimal RF interference.

Chirp Spread Spectrum Technology Deep Dive

CSS RTLS Technology Fundamentals

Chirp Spread Spectrum (CSS) technology provides long-range, low-power positioning with excellent penetration through obstacles and interference resistance, making it ideal for large outdoor areas and challenging RF environments where other technologies may struggle to maintain reliable communication.

Technology Advantages

Extended Range Coverage

1000m+ range with excellent signal propagation characteristics.

Superior Penetration

Resilient performance through walls, vegetation, and obstacles.

Ultra-Low Power

5–10 year battery life with optimized power consumption.

Interference Immunity

Robust performance in noisy RF environments.

Technical Specifications

Core Features

- Chirp modulation technology

- Time-difference-of-arrival (TDoA)

- Frequency hopping capability

- Adaptive data rate optimization

- Multi-path interference rejection

- Long-range mesh networking

- Environmental adaptation

- Scalable network topology

Ideal Deployment Scenarios

Large Outdoor Areas

- Mining and quarry operations

- Construction site monitoring

- Port and shipyard tracking

- Agricultural asset management

- Utility infrastructure monitoring

Challenging Environments

- Underground facilities

- Dense urban environments

- Industrial complexes

- Remote monitoring stations

- Harsh weather conditions

Long-Term Deployments

- Environmental monitoring

- Wildlife tracking systems

- Infrastructure asset management

- Remote equipment monitoring

- Security perimeter systems

CSS RTLS Solutions & Resources

Long-Range Applications

Industry Solutions

Deploy Long-Range CSS RTLS

Achieve 1000m+ range with 5–10 year battery life for challenging outdoor environments and remote monitoring.

Manufacturing & Warehousing RTLS Applications

Manufacturing RTLS Fundamentals

Manufacturing and warehousing operations achieve unprecedented operational excellence through RTLS implementation, delivering real-time visibility into asset utilization, workflow optimization, and safety compliance. Advanced positioning technology enables data-driven decision making, predictive maintenance, and lean manufacturing principles while ensuring worker safety and regulatory compliance across complex industrial environments.

Production & Assembly Applications

Work-in-Progress Tracking

Real-time visibility into production status, bottleneck identification, and cycle time optimization across assembly lines and manufacturing cells.

Tool & Equipment Management

Automated tool tracking, utilization monitoring, and maintenance scheduling to maximize equipment effectiveness and reduce downtime.

Worker Safety & Compliance

Personnel monitoring in hazardous areas, emergency evacuation procedures, and OSHA compliance reporting for industrial safety.

Quality Control Integration

Automated quality checkpoints, traceability documentation, and defect tracking throughout the manufacturing process.

Warehouse & Logistics Applications

Inventory Management

Real-time inventory tracking, automated cycle counting, and dynamic slotting optimization for maximum warehouse efficiency.

Material Handling Equipment

Forklift tracking, utilization analytics, and collision avoidance systems for improved safety and productivity.

Pick Path Optimization

Dynamic route optimization, labor productivity analytics, and performance benchmarking for warehouse operations.

Cross-Docking Operations

Flow-through optimization, dock door management, and trailer tracking for efficient distribution operations.

Manufacturing RTLS Technical Specifications

Advanced Manufacturing Features

- Predictive maintenance scheduling

- Lean manufacturing analytics

- OEE (Overall Equipment Effectiveness) tracking

- Automated compliance reporting

- Digital twin integration

- Multi-site deployment management

- Hazardous area certification (ATEX/IECEx)

- Machine learning optimization

- Energy consumption monitoring

- Supply chain visibility integration

Manufacturing Implementation Criteria

Environmental Considerations

- High-temperature environments (foundries, steel mills)

- Chemical exposure and corrosive atmospheres

- Electromagnetic interference from heavy machinery

- Dust, moisture, and contamination resistance

- Intrinsically safe requirements for hazardous areas

- 24/7 continuous operation requirements

Performance Requirements

- Sub-meter accuracy for precision manufacturing

- Real-time updates (1–10 second intervals)

- Scalability to thousands of tracked assets

- Integration with existing MES/WMS systems

- Historical data retention and analytics

- Multi-site deployment and management

ROI & Business Impact

- 25–40% asset utilization improvement

- 15–30% productivity increase

- 70–90% search time reduction

- 12–18 months typical ROI timeline

- $2–8M annual savings per facility

- Measurable safety incident reduction

Transform Your Manufacturing Operations

Achieve 25–40% asset utilization improvement and 15–30% productivity increase with manufacturing RTLS solutions.

Healthcare RTLS Applications

Healthcare RTLS Fundamentals

Healthcare organizations leverage RTLS technology to enhance patient safety, optimize clinical workflows, and improve operational efficiency. Real-time location systems provide critical visibility into medical equipment, staff, and patient movements, enabling better resource allocation, faster emergency response, and improved patient outcomes while ensuring regulatory compliance and cost optimization across complex healthcare environments.

Patient Safety & Care Applications

Patient Monitoring & Safety

Real-time patient location tracking, wandering prevention, fall risk monitoring, and infant security systems for comprehensive patient safety.

Emergency Response

Code team optimization, emergency equipment location, rapid response coordination, and critical care workflow enhancement.

Infection Control

Contact tracing, isolation compliance monitoring, hand hygiene tracking, and outbreak prevention through automated surveillance.

Medication Safety

Medication administration verification, pharmacy workflow optimization, and controlled substance tracking for patient safety.

Operational Efficiency Applications

Medical Equipment Management

Real-time equipment tracking, utilization analytics, maintenance scheduling, and asset optimization across healthcare facilities.

Staff Workflow Optimization

Nurse productivity analytics, physician rounding efficiency, and staff allocation optimization for improved patient care delivery.

Patient Flow Management

ED throughput optimization, bed management, discharge coordination, and patient journey analytics for operational excellence.

Environmental Monitoring

Temperature-sensitive medication tracking, clean room monitoring, and environmental compliance for regulatory requirements.

Healthcare RTLS Technical Specifications

Advanced Healthcare Features

- HIPAA-compliant data encryption

- Real-time clinical alerts and notifications

- Automated hand hygiene compliance

- Emergency evacuation management

- Predictive equipment maintenance

- Multi-campus deployment support

- Clinical workflow analytics

- Regulatory audit trail generation

- Patient satisfaction optimization

- Revenue cycle integration

Healthcare Implementation Criteria

Clinical Requirements

- Patient safety and privacy protection

- Clinical workflow integration

- Emergency response optimization

- Infection control capabilities

- Medical device compatibility

- 24/7 reliable operation

Regulatory Compliance

- HIPAA privacy and security rules

- Joint Commission standards

- FDA medical device regulations

- CMS quality reporting requirements

- State health department regulations

- Cybersecurity framework compliance

Clinical & Financial Impact

- 30–50% equipment utilization improvement

- 20–35% staff productivity increase

- 60–80% emergency response improvement

- 10–16 months typical ROI timeline

- $1–5M annual operational savings

- Measurable patient satisfaction gains

Enhance Healthcare Operations

Improve patient safety and operational efficiency with 30–50% equipment utilization improvement and 20–35% staff productivity increase.

Logistics & Supply Chain RTLS Applications

Supply Chain RTLS Fundamentals

Logistics and supply chain operations achieve unprecedented visibility and optimization through RTLS implementation, enabling real-time tracking of goods, vehicles, and personnel across complex distribution networks. Advanced positioning technology delivers actionable insights for inventory management, route optimization, and delivery performance while ensuring compliance and customer satisfaction throughout the entire supply chain ecosystem.

Warehouse & Distribution Applications

Inventory Management

Real-time inventory tracking, automated cycle counting, dynamic slotting optimization, and perpetual inventory accuracy for warehouse operations.

Labor Productivity

Pick path optimization, performance analytics, workload balancing, and productivity benchmarking for warehouse staff efficiency.

Material Handling Equipment

Forklift tracking, utilization monitoring, collision avoidance, and maintenance scheduling for equipment optimization.

Cross-Docking Operations

Flow-through optimization, dock door management, trailer tracking, and turnaround time reduction for distribution efficiency.

Transportation & Delivery Applications

Fleet Management

Vehicle tracking, route optimization, fuel efficiency monitoring, and driver performance analytics for transportation optimization.

Last-Mile Delivery

Delivery route optimization, customer notifications, proof of delivery, and delivery performance analytics for customer satisfaction.

Cold Chain Management

Temperature monitoring, compliance tracking, automated alerts, and chain of custody documentation for sensitive products.

Yard Management

Trailer tracking, yard optimization, appointment scheduling, and asset visibility for distribution center operations.

Logistics RTLS Technical Specifications

| Specification | Warehouse Operations | Transportation |

|---|---|---|

| Positioning Accuracy | 1-3m (zone-level tracking) | 5-50m (GPS + cellular) |

| Update Rate | 10-60 seconds (periodic) | 1-15 minutes (route dependent) |

| Coverage Area | 500K – 5M+ sq ft facilities | Regional to global networks |

| Tracked Assets | 10K – 500K+ inventory items | Vehicles, trailers, containers |

| Environmental Rating | IP54–IP65 (warehouse) | IP67–IP68 (outdoor/mobile) |

| Battery Life | 12–60 months (asset tags) | 6–24 months (vehicle trackers) |

| Integration | WMS, TMS, ERP systems | Fleet management, TMS, CRM |

Advanced Supply Chain Features

- Predictive analytics and demand forecasting

- Automated replenishment optimization

- Multi-modal transportation tracking

- Customer delivery notifications

- Sustainability and carbon footprint tracking

- Multi-site network optimization

- Supply chain risk management

- Blockchain integration for traceability

- AI-powered route optimization

- Real-time supply chain visibility

Supply Chain Implementation Criteria

Operational Requirements

- Multi-site deployment capabilities

- Scalable architecture for growth

- Integration with existing systems

- Real-time data processing

- Mobile workforce support

- 24/7 operational reliability

Performance Metrics

- Inventory accuracy improvement

- Order fulfillment speed

- Transportation efficiency

- Customer satisfaction scores

- Cost reduction achievements

- Sustainability impact measurement

Business Impact & ROI

- 20–40% inventory reduction

- 25–45% productivity improvement

- 30–60% accuracy improvement

- 8–14 months typical ROI timeline

- $5–25M annual network savings

- Enhanced competitive advantage

Optimize Your Supply Chain

Achieve 20–40% inventory reduction and 25–45% productivity improvement with supply chain RTLS solutions.

Operational Efficiency Benefits

Operational Efficiency Fundamentals

RTLS technology transforms operational efficiency by providing real-time visibility into asset utilization, workflow optimization, and resource allocation. Organizations achieve measurable improvements in productivity, cost reduction, and operational excellence through data-driven insights and automated processes that eliminate waste and optimize performance across all operational dimensions.

Efficiency Enhancement Methods

Asset Utilization

Real-time tracking maximizes equipment usage and availability.

Process Optimization

Data-driven insights streamline workflows and eliminate bottlenecks.

Search Elimination

Instant asset location reduces time spent searching for resources.

Productivity Analytics

Performance metrics enable continuous improvement initiatives.

Resource Allocation

Optimal distribution of assets based on real-time demand.

Automation Integration

Seamless connection with existing systems and processes.

Performance Specifications

| Efficiency Metric | Before RTLS | After RTLS | Improvement |

|---|---|---|---|

| Asset Utilization Rate | 45–60% | 70–85% | +25–40% increase |

| Daily Search Time | 15–30 min/day | 2–5 min/day | 70–90% reduction |

| Process Cycle Time | 100% baseline | 75–85% of baseline | 15–25% faster |

| Labor Productivity | 100% baseline | 115–130% of baseline | 15–30% improvement |

| Inventory Accuracy | 85–90% | 95–99% | 5–14% improvement |

| Maintenance Efficiency | Reactive scheduling | Predictive scheduling | 30–50% optimization |

Advanced Efficiency Features

Implementation Benefits

- Real-time asset visibility across facilities

- Elimination of manual search processes

- Automated compliance reporting systems

- Basic utilization analytics and insights

- Process optimization recommendations

- Predictive maintenance scheduling

Long-term Value

- AI-driven optimization algorithms

- Digital twin integration capabilities

- Continuous improvement cycles

- Strategic decision support systems

- Advanced analytics and reporting

- Integration with existing ERP systems

Implementation Timeline & Impact

Immediate (0–3 months)

- Real-time asset visibility

- Elimination of manual searches

- Automated compliance reporting

- Basic utilization analytics

Medium-term (3–12 months)

- Process optimization insights

- Predictive maintenance scheduling

- Advanced analytics and reporting

- Integration with existing systems

Long-term (12+ months)

- AI-driven optimization

- Digital twin integration

- Continuous improvement cycles

- Strategic decision support

Optimal Implementation Scenarios

High-Asset Environments

- Manufacturing facilities with extensive tooling

- Hospitals with critical medical equipment

- Construction sites with mobile assets

- Warehouses with material handling equipment

- Research facilities with specialized instruments

Process-Intensive Operations

- Multi-stage production workflows

- Complex assembly operations

- Quality control processes

- Maintenance and service operations

- Supply chain coordination

Large-Scale Facilities

- Multi-building campus environments

- Extensive warehouse operations

- Large healthcare systems

- Educational institutions

- Government and military facilities

Explore Related Solutions & Resources

Implementation Services

Ready to Optimize Your Operations?

Discover how RTLS can transform your operational efficiency with measurable ROI and proven results.

Safety & Compliance Benefits

Safety & Compliance Fundamentals

RTLS technology revolutionizes workplace safety and regulatory compliance by providing real-time monitoring, automated alerts, and comprehensive documentation. Organizations achieve significant reductions in safety incidents, improved emergency response times, and streamlined compliance reporting while creating safer work environments and protecting their most valuable asset – their people.

Safety Enhancement Methods

Real-Time Monitoring

Continuous personnel location and safety status tracking.

Emergency Response

Automated detection and rapid response coordination.

Compliance Automation

Automated regulatory monitoring and reporting systems.

Zone-Based Controls

Restricted area monitoring and access management.

Incident Prevention

Proactive risk identification and mitigation strategies.

Training Integration

Safety training effectiveness and compliance tracking.

Safety Performance Specifications

| Safety Metric | Before RTLS | After RTLS | Improvement |

|---|---|---|---|

| Safety Incidents | Baseline rate | Reduced incidents | 60–80% reduction |

| Emergency Response Time | 5–15 minutes | 1–5 minutes | 50–70% faster |

| Compliance Accuracy | 80–90% | 95–99% | 95%+ adherence |

| Training Effectiveness | Manual tracking | Automated verification | 40% improvement |

| Risk Assessment | Periodic reviews | Real-time monitoring | Continuous coverage |

| Audit Preparation | Weeks of preparation | Automated reports | 90% time savings |

Advanced Safety Features

Safety Monitoring

- Real-time personnel location tracking

- Automated safety zone enforcement

- Emergency alert and notification systems

- Incident detection and response protocols

- Safety equipment compliance monitoring

- Environmental hazard detection integration

Compliance Management

- Automated regulatory reporting systems

- Training completion verification

- Audit trail generation and maintenance

- Policy enforcement automation

- Risk assessment documentation

- Continuous compliance monitoring

Optimal Implementation Scenarios

High-Risk Industries

- Chemical and petrochemical facilities

- Mining and extraction operations

- Construction and heavy industry

- Nuclear and power generation

- Oil and gas operations

Regulated Environments

- Healthcare and pharmaceutical

- Food and beverage processing

- Aerospace and defense

- Financial services facilities

- Government and public safety

Large Workforce Operations

- Manufacturing plants with 500+ workers

- Distribution centers and warehouses

- Educational institutions

- Corporate campuses

- Event and entertainment venues

Explore Safety & Compliance Resources

Industry Guides

Enhance Your Safety & Compliance

Transform workplace safety with RTLS technology that delivers 60–80% reduction in safety incidents.

Financial & ROI Benefits

Financial & ROI Fundamentals

RTLS implementations deliver exceptional financial returns through measurable cost reductions, productivity improvements, and operational optimizations. Organizations typically achieve 150–300% ROI within 12–18 months through reduced labor costs, improved asset utilization, decreased inventory carrying costs, and enhanced operational efficiency that directly impacts the bottom line.

Financial Enhancement Methods

Cost Reduction

Operational cost savings through efficiency and waste elimination.

Revenue Optimization

Increased revenue through productivity and customer satisfaction.

Risk Mitigation

Reduced financial exposure through safety and compliance.

ROI Achievement

Rapid return on investment with sustained benefits.

Asset Optimization

Maximized asset value through utilization improvements.

Performance Analytics

Data-driven financial insights and decision support.

Financial Performance Specifications

| Financial Metric | Before RTLS | After RTLS | Improvement |

|---|---|---|---|

| Operational Costs | Baseline costs | Reduced costs | 20–35% reduction |

| Revenue Growth | Standard growth | Accelerated growth | 10–25% increase |

| ROI Timeline | 24–36 months | 12–18 months | 50% faster payback |

| Productivity Value | 100% baseline | 115–130% baseline | 15–30% improvement |

| Asset ROI | Standard utilization | Optimized utilization | 25–40% increase |

| Risk Costs | Standard exposure | Reduced exposure | 60–80% decrease |

Advanced Financial Features

Cost Management

- Real-time cost tracking and analysis

- Automated expense optimization

- Resource allocation efficiency

- Waste reduction and elimination

- Energy consumption optimization

- Maintenance cost reduction

Revenue Enhancement

- Productivity-driven revenue growth

- Customer satisfaction improvements

- Service delivery optimization

- Quality enhancement initiatives

- Competitive advantage development

- Market expansion opportunities

ROI Timeline & Financial Impact

Immediate (0–6 months)

- 10–15% operational cost reduction

- Elimination of search-related losses

- Basic productivity improvements

- Initial asset utilization gains

Medium-term (6–18 months)

- 20–30% total cost reduction

- Revenue growth acceleration

- Full ROI achievement

- Competitive advantage establishment

Long-term (18+ months)

- 150–300% cumulative ROI

- Sustained competitive advantages

- Strategic growth enablement

- Market leadership positioning

Optimal Implementation Scenarios

High-Value Operations

- Facilities with expensive equipment

- High-volume production environments

- Critical infrastructure operations

- Research and development facilities

- Precision manufacturing operations

Cost-Sensitive Industries

- Competitive manufacturing sectors

- Logistics and distribution

- Healthcare cost management

- Energy and utilities

- Retail and e-commerce

Growth-Focused Organizations

- Scaling manufacturing operations

- Expanding healthcare systems

- Growing logistics networks

- Technology companies

- Service organizations

Maximize Your RTLS Investment

High-ROI Applications

Calculate Your RTLS ROI

Discover how RTLS can deliver 150–300% ROI with 12–18 month payback periods and sustained financial benefits.

RTLS Assessment & Planning Phase

RTLS Assessment & Planning Fundamentals

Comprehensive RTLS assessment and planning establishes the foundation for successful implementation through systematic site analysis, requirements gathering, stakeholder alignment, and technology selection. This critical phase ensures optimal system design, accurate cost estimation, and realistic timeline development while identifying potential challenges and mitigation strategies for complex operational environments.

Assessment Methods

Site Survey & Analysis

Comprehensive facility mapping, RF environment assessment, and infrastructure evaluation.

Requirements Gathering

Stakeholder interviews, use case definition, and performance criteria establishment.

Technology Evaluation

RTLS technology comparison, vendor assessment, and solution architecture design.

Risk Assessment

Implementation risk identification, mitigation planning, and contingency development.

Planning Deliverables

- Detailed site survey report with RF mapping

- Comprehensive requirements specification document

- Technology selection matrix with vendor comparison

- System architecture design and topology

- Implementation timeline with critical milestones

- Budget estimation with ROI projections

- Risk assessment with mitigation strategies

- Stakeholder communication and training plan

Assessment Criteria Framework

| Assessment Area | Key Metrics | Timeline | Stakeholders |

|---|---|---|---|

| Facility Analysis | Coverage, RF interference, obstacles | 1–2 weeks | Facilities, IT, Operations |

| Use Case Definition | Accuracy, latency, scalability | 2–3 weeks | Operations, Management, End Users |

| Technology Selection | Performance, cost, integration | 1–2 weeks | IT, Procurement, Engineering |

| Budget Planning | CAPEX, OPEX, ROI timeline | 1 week | Finance, Management, Procurement |

Advanced Features

- AI-powered site analysis and optimization recommendations

- Digital twin modeling for virtual testing and validation

- Automated ROI calculation with sensitivity analysis

- Integration assessment with existing enterprise systems

- Compliance verification for industry-specific regulations

- Change management planning with user adoption strategies

- Vendor evaluation with technical and commercial scoring

- Risk mitigation planning with contingency scenarios

Implementation Selection Criteria

Facility Characteristics

- Complex multi-level environments

- High RF interference areas

- Large coverage area requirements

- Mixed indoor/outdoor operations

- Dynamic operational layouts

Business Requirements

- High-value asset tracking needs

- Safety and compliance mandates

- Operational efficiency goals

- Integration with existing systems

- Scalability for future growth

Technical Considerations

- Sub-meter accuracy requirements

- Real-time tracking capabilities

- Enterprise system integration

- Robust data analytics needs

- Long-term maintenance support

Start Your RTLS Assessment

Begin your RTLS journey with comprehensive assessment and strategic planning for optimal implementation success.

RTLS Infrastructure Design Phase

RTLS Infrastructure Design Fundamentals

RTLS infrastructure design transforms assessment findings into detailed technical specifications, network architecture, and deployment plans. This phase encompasses anchor placement optimization, network topology design, power and connectivity planning, and integration architecture to ensure optimal system performance, scalability, and reliability across complex operational environments.

Design Components

Anchor Placement Optimization

Strategic positioning using coverage modeling, interference analysis, and geometric optimization.

Network Architecture Design

Topology planning, bandwidth allocation, and redundancy implementation for reliable operation.

Power & Connectivity Planning

Electrical infrastructure, PoE distribution, and backup power systems for continuous operation.

Integration Architecture

Enterprise system connectivity, API design, and data flow optimization for seamless integration.

Design Deliverables

- Detailed anchor placement drawings with coordinates

- Network topology diagrams and specifications

- Power and connectivity infrastructure plans

- Integration architecture and API documentation

- Coverage analysis and performance modeling

- Bill of materials with technical specifications

- Installation guidelines and procedures

- Testing and validation protocols

Infrastructure Design Specifications

| Design Element | Specifications | Coverage | Redundancy |

|---|---|---|---|

| UWB Anchors | 6.5GHz, 1000 tags/anchor | 100m radius | N+1 configuration |

| Network Backbone | Gigabit Ethernet, PoE+ | Facility-wide | Dual-path routing |

| Processing Servers | Edge computing, real-time | Zone-based | Active-passive cluster |

| Data Storage | Time-series database | Enterprise-wide | RAID + backup |

Advanced Features

- AI-powered anchor placement optimization algorithms

- Dynamic coverage modeling with environmental factors

- Automated network configuration and provisioning

- Real-time performance monitoring and alerting

- Scalable architecture for future expansion

- Enterprise security integration and compliance

- Edge computing for low-latency processing

- Hybrid cloud deployment with local redundancy

Design Selection Criteria

Performance Requirements

- Sub-meter accuracy specifications

- Real-time tracking capabilities

- High-density tag support

- Low-latency data processing

- Robust interference immunity

Scalability Factors

- Modular architecture design

- Future expansion capabilities

- Technology upgrade pathways

- Multi-site deployment support

- Cloud-hybrid architectures

Integration Requirements

- Enterprise system connectivity

- API and middleware integration

- Security and compliance alignment

- Data analytics and reporting

- Mobile and web application support

Professional Infrastructure Design

Get expert infrastructure design and architecture planning to ensure optimal RTLS performance and scalability for your facility.

RTLS Pilot Deployment Phase

RTLS Pilot Deployment Fundamentals

RTLS pilot deployment validates system design through controlled, limited-scope implementation that tests performance, identifies optimization opportunities, and refines operational procedures. This critical phase provides real-world validation, user feedback collection, and process refinement before full-scale rollout, ensuring successful adoption and maximum return on investment.

Pilot Activities

Limited Infrastructure Deployment

Strategic installation of core system components in representative operational areas.

Performance Validation Testing

Comprehensive accuracy, latency, and reliability testing under real operational conditions.

User Training & Feedback

End-user training programs with feedback collection and process refinement.

Process Optimization

Workflow integration, system tuning, and operational procedure development.

Pilot Outcomes

- Validated system performance metrics and accuracy

- Optimized configuration parameters and settings

- Refined operational procedures and workflows

- Trained user base with documented feedback

- Identified integration challenges and solutions

- Updated implementation timeline and budget

- Risk mitigation strategies and contingency plans

- Go/no-go recommendation for full deployment

Pilot Performance Metrics

| Metric Category | Target Performance | Measurement Method | Success Criteria |

|---|---|---|---|

| Positioning Accuracy | <30cm (95% confidence) | Static & dynamic testing | Meets design specifications |

| System Latency | <100ms end-to-end | Real-time monitoring | Consistent performance |

| Tag Battery Life | 3+ years operation | Power consumption analysis | Projected lifecycle met |

| User Adoption | 90% user satisfaction | Surveys & interviews | Positive feedback scores |

Advanced Features

- Automated performance monitoring and alerting systems

- Machine learning-based optimization recommendations

- Real-time dashboard for pilot metrics and KPIs

- User feedback collection and analysis platform

- A/B testing capabilities for configuration optimization

- Integration testing with existing enterprise systems

- Scalability testing for full deployment planning

- Security and compliance validation protocols

Pilot Selection Criteria

Pilot Area Selection

- Representative operational environment

- Manageable scope and complexity

- High-impact use case validation

- Accessible for testing and monitoring

- Minimal disruption to operations

User Group Selection

- Technology-savvy early adopters

- Representative of end-user base

- Committed to feedback provision

- Available for training sessions

- Influential within organization

Success Validation

- Performance metrics achievement

- User satisfaction and adoption

- Integration success with systems

- Operational workflow improvement

- ROI validation and projection

Expert Pilot Implementation

Launch your RTLS pilot with professional implementation services to validate performance and optimize configuration before full deployment.

RTLS Full-Scale Rollout Phase

RTLS Full-Scale Rollout Fundamentals

RTLS full-scale rollout executes comprehensive system deployment across all operational areas, incorporating pilot learnings, optimized configurations, and proven procedures. This phase encompasses phased installation, comprehensive training programs, change management, and performance monitoring to ensure successful adoption and sustained value realization across the entire organization.

Rollout Activities

Phased Infrastructure Deployment

Systematic installation across all operational areas with minimal business disruption.

Comprehensive User Training

Organization-wide training programs with role-specific curricula and certification.

Change Management Execution

Structured change management with communication, support, and adoption strategies.

Performance Monitoring

Continuous system monitoring, optimization, and performance validation.

Rollout Deliverables

- Complete system deployment across all areas

- Trained and certified user base organization-wide

- Integrated enterprise system connectivity

- Operational procedures and documentation

- Performance monitoring and alerting systems

- Help desk and support infrastructure

- Change management and communication programs

- Success metrics tracking and reporting

Rollout Timeline & Milestones

| Phase | Duration | Key Activities | Success Criteria |

|---|---|---|---|

| Phase 1: Core Areas | 4–6 weeks | Critical operational zones | 95% system availability |

| Phase 2: Secondary Areas | 6–8 weeks | Support and storage areas | User adoption >80% |

| Phase 3: Integration | 2–4 weeks | Enterprise system connectivity | Full data integration |

| Phase 4: Optimization | 2–3 weeks | Performance tuning & training | Target KPIs achieved |

Advanced Features

- Automated deployment orchestration and configuration management

- Real-time rollout progress tracking and milestone reporting

- Intelligent user training scheduling and progress monitoring

- Change impact assessment and mitigation strategies

- Performance benchmarking and optimization recommendations

- Enterprise integration testing and validation protocols

- User adoption analytics and engagement measurement

- Continuous improvement feedback loops and optimization

Rollout Selection Criteria

Deployment Strategy

- Risk-based phased approach

- Business continuity preservation

- Resource optimization and scheduling

- Minimal operational disruption

- Scalable deployment methodology

Training & Adoption

- Role-specific training curricula

- Multi-modal learning approaches

- Certification and competency validation

- Change champion network development

- Continuous support and reinforcement

Success Measurement

- System performance and availability

- User adoption and satisfaction metrics

- Business process improvement validation

- ROI achievement and tracking

- Long-term sustainability indicators

Full-Scale RTLS Deployment

Scale your RTLS solution across your entire facility with comprehensive deployment and integration services for maximum operational impact.

RTLS Optimization & Support Phase

RTLS Optimization & Support Fundamentals

RTLS optimization and support ensures sustained system performance, continuous improvement, and long-term value realization through proactive monitoring, predictive maintenance, performance tuning, and user support. This ongoing phase encompasses system optimization, user training reinforcement, technology updates, and strategic enhancement planning for evolving business requirements.

Support Activities

Continuous Performance Monitoring

Real-time system monitoring, predictive analytics, and proactive issue resolution.

System Optimization & Tuning

Performance optimization, configuration refinement, and efficiency improvements.

User Support & Training

Ongoing user support, refresher training, and competency development programs.

Technology Updates & Enhancements

Software updates, feature enhancements, and technology roadmap implementation.

Support Deliverables

- 24/7 system monitoring and alerting infrastructure

- Predictive maintenance and optimization recommendations

- Regular performance reports and KPI dashboards

- User support portal and knowledge base

- Ongoing training programs and certification updates

- Technology roadmap and enhancement planning

- System backup and disaster recovery procedures

- Vendor relationship management and SLA monitoring

Support Service Levels

| Service Category | Response Time | Resolution Target | Availability SLA |

|---|---|---|---|

| Critical System Issues | 15 minutes | 4 hours | 99.9% uptime |

| Performance Degradation | 1 hour | 24 hours | 99.5% performance |

| User Support Requests | 2 hours | 48 hours | 95% satisfaction |

| Enhancement Requests | 1 business day | 30 days | Quarterly releases |

Advanced Features

- AI-powered predictive maintenance and failure prevention

- Machine learning-based performance optimization algorithms

- Automated system health monitoring and self-healing capabilities

- Advanced analytics for usage patterns and optimization opportunities

- Proactive capacity planning and scalability recommendations

- Integrated ticketing system with automated escalation procedures

- Remote diagnostic capabilities and virtual troubleshooting

- Continuous improvement program with ROI tracking and validation

Monitoring & Maintenance

- Proactive system health monitoring

- Predictive maintenance scheduling

- Performance trend analysis

- Automated alerting and escalation

- Regular system optimization reviews

User Experience

- Multi-channel support availability

- Self-service knowledge base

- Regular training and certification

- User feedback collection and analysis

- Continuous improvement initiatives

Strategic Enhancement

- Technology roadmap alignment

- Business requirement evolution

- ROI optimization and validation

- Scalability planning and execution

- Innovation adoption and integration

Ongoing RTLS Optimization

Maximize your RTLS ROI with continuous optimization and professional managed services for sustained performance excellence.

Location Engine Processing

Intelligent Location Processing

The location engine is the computational brain of RTLS systems, transforming raw signal data into precise position coordinates through advanced algorithms, machine learning, and real-time analytics to deliver actionable location intelligence.

Processing Capabilities

Signal Processing

Advanced algorithms for noise filtering, multipath mitigation, and signal enhancement

Position Calculation

Multi-algorithm fusion using trilateration, triangulation, and machine learning models

Data Fusion

Integration of multiple sensor inputs for enhanced accuracy and reliability

Real-time Analytics

Instant processing and analysis of location data with sub-second response times

Performance Metrics

Advanced Features

- Machine learning optimization

- Predictive path modeling

- Anomaly detection algorithms

- Multi-zone handoff management

- Historical data analytics

- Custom geofencing rules

- Alert and notification engine

- Third-party system integration

Algorithm Selection Framework

Accuracy Requirements

- Sub-meter: Basic trilateration

- Centimeter: Advanced fusion

- Mission-critical: ML-enhanced

- Dynamic optimization

Environmental Adaptation

- Multipath mitigation

- Interference filtering

- Dynamic calibration

- Environmental learning

Integration Capabilities

- Real-time API access

- Historical data queries

- Custom analytics dashboards

- Enterprise system integration

Experience Location Intelligence