A Comprehensive Guide to RTLS Digital Twins

What are RTLS Digital Twins?

RTLS digital twins are intelligent operational systems that merge real-time location tracking (indoor positioning systems) with dynamic 3D simulation models, by combining live spatial intelligence with digital twin modeling, they deliver centimeter-level accuracy and sub-second latency for reality-based simulation and actionable insights.

Stage 1

Real-Time Location Intelligence Collection

LocaXion RTLS captures precise spatial data and movement patterns across your entire operation.

Stage 2

Digital Twin Dynamic Optimization

Location data feeds Digital Twin models for real-time simulation and predictive optimization.

Stage 3

Autonomous Operational Enhancement

Optimized insights automatically improve operations, generating new data for continuous improvement.

Why Traditional Digital Twins Fail Without RTLS Integration?

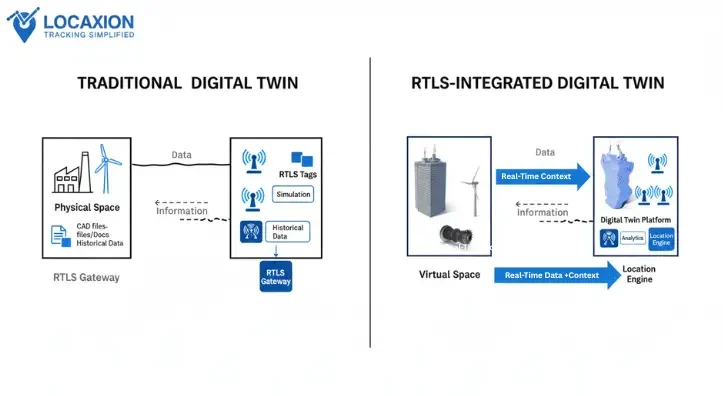

Traditional Digital Twins operate on static assumptions and outdated data, while RTLS + Digital Twin integrated platformsion delivers real-time spatial intelligence that transforms reactive reporting into proactive operational control.

Traditional Digital Twins

The Location Intelligence Gap

- Static Spatial Assumptions

Models assume assets stay where they're supposed to be - Yesterday's Reality

Decisions based on hours-old or manually updated data - Reactive Reporting

Tells you what went wrong after productivity was already lost - Simulation Guesswork

What-if scenarios based on theoretical data, not operational reality

RTLS + Digital Twin

Real-Time Location Intelligence

- Dynamic Spatial Reality

Models reflect actual asset locations and movements in real-time - Live Operational Data

Decisions based on current reality, updated every second - Proactive Control

Prevents problems before they impact productivity - Reality-Based Simulation

What-if scenarios using your actual operational patterns and data

Levels of RTLS Digital Twin Maturity

Understanding RTLS Digital Twin implementation requires recognizing it as an evolving process, not a one-time deployment. Each stage delivers immediate value while building the foundation for data-driven insights, predictive optimization, and smarter operational control.

Real-Time Visibility

Foundation of Spatial Intelligence

Complete spatial awareness of every asset, person, and process

- Find any asset in seconds

- Live facility-wide overview

- Historical pattern analysis

Measure & Control

Operational Intelligence

Transform location data into actionable insights and predictions

- Spatial process analytics

- Predictive intelligence

- Automated control systems

Planning & Simulation

Autonomous Enhancement

Test changes digitally and enable self-improving operations

- Reality-based modeling

- What-if scenario testing

- Autonomous optimization

Why Traditional Digital Twins Fail?

Traditional Digital Twins operate on static assumptions and outdated data, while RTLS + Digital Twin integration delivers real-time spatial intelligence that transforms reactive reporting into proactive operational control.

Traditional Digital Twins

The Location Intelligence Gap

- Static Spatial Assumptions

Models assume assets stay where they're supposed to be - Yesterday's Reality

Decisions based on hours-old or manually updated data - Reactive Reporting

Tells you what went wrong after productivity was already lost - Simulation Guesswork

What-if scenarios based on theoretical data, not operational reality

RTLS + Digital Twin

Real-Time Location Intelligence

- Dynamic Spatial Reality

Models reflect actual asset locations and movements in real-time - Live Operational Data

Decisions based on current reality, updated every second - Proactive Control

Prevents problems before they impact productivity - Reality-Based Simulation

What-if scenarios using your actual operational patterns and data

Core Components of RTLS-powered Digital Twin

Discover the five-layer architecture of an enterprise digital twin platform that transforms raw location data into autonomous operational intelligence through real-time spatial processing and AI-powered optimization.

Physical Reality Layer

Spatially Enhanced

- RTLS Infrastructure (UWB, BLE, RFID)

- Environmental Sensors with Spatial Correlation

- Industrial-Grade Asset Tags & Wearables

Real-Time Data Fusion Layer

- Spatial-Temporal Processing (<1s updates)

- Multi-Sensor Integration & Correlation

- AI-Powered Movement Intelligence

Digital Twin Modeling Layer

Spatially Enhanced

- 4D Spatial Models (3D + Time)

- Physics-Based Real-Time Simulation

- Dynamic Process Optimization Models

Location Intelligence Analytics Layer

- Spatial Analytics Engine

- Predictive Location Modeling

- Autonomous Anomaly Detection

Autonomous Control & Interface Layer

- Real-Time Control Systems

- Predictive Dashboards

- Automated Response Systems

The Power of Integrated Architecture

Real-Time Intelligence

Sub-second data processing enables immediate response to operational changes and anomalies

Predictive Optimization

AI-powered analytics predict and prevent issues before they impact operations

Autonomous Control

Self-optimizing systems continuously improve operations without manual intervention

An In-Depth Analysis of RTLS Technologies

For comprehensive RTLS technology comparison and selection guidance, explore our complete

RTLS Technology GuideReal-World Use Cases of RTLS Digital Twin Platforms

Learn how embedding real-time location intelligence into digital twin platforms revolutionizes operations in manufacturing, healthcare, and logistics across three progressive stages: Level 1 – Visibility, Level 2 – Measure & Control, and Level 3 – Planning & Simulation.

Manufacturing

From Manual Oversight to Autonomous Production Intelligence Watch how a traditional production line evolves into a self-optimizing intelligent system through progressive RTLS Digital Twin implementation

Live Production View

"Production line goes down. Is it a missing test jig for quality checks? Is the required sub-assembly still in the paint shop? Is the certified operator on break or temporarily reassigned?"

Hidden Process Insights

"Your Digital Twin visualizes the 'spaghetti diagram' of your material handlers, but goes deeper. It reveals that 40% of all forklift and AGV travel is 'empty runs.'"

What If Scenarios

"Management wants to introduce a new product line into your existing facility. Where does the new cell go? How will it impact the flow of existing materials and the demand on shared resources?"

Healthcare: From Equipment Searches to Predictive Patient Care

Transform healthcare operations from reactive equipment management to proactive patient flow optimization

Instant Equipment Location

"Nurses were spending 30% of their shift looking for equipment. Now they find what they need in seconds, giving them more time for patient care."

Predictive Patient Flow

"We can now predict ED bottlenecks 2 hours before they happen and automatically adjust staffing and bed assignments to prevent overcrowding."

Autonomous Care Coordination

"The system now automatically coordinates room cleaning, equipment delivery, and staff assignments based on real-time patient needs and flow patterns."

Logistics: From Manual Tracking to Autonomous Fulfillment

Evolution from basic inventory tracking to fully autonomous warehouse operations with predictive optimization

Complete Warehouse Visibility

"We eliminated the 'lost inventory' problem completely. Every pallet, every piece of equipment, every worker is tracked in real-time across our 500,000 sq ft facility."

Intelligent Flow Optimization

"The system identified that 40% of our forklift movements were empty runs. We redesigned our workflows and improved efficiency by 35% without adding equipment."

Autonomous Fulfillment

"Our warehouse now operates like a self-organizing organism. The system automatically optimizes picking routes, manages AGV traffic, and predicts maintenance needs."

RTLS Digital Twin Implementation Guide

The six-phase RTLS digital twin implementation framework provides a structured path for successful deployment, seamless user adoption, and measurable long-term value. By aligning technology, processes, and people, it enables organizations to scale digital twin platforms across complex enterprise environments with confidence.

Strategic Assessment & Use Case Definition

Current state analysis and location intelligence audit with use case prioritization and ROI projections

Key Deliverables:- Current state analysis

- Use case prioritization

- Success metrics definition

Architecture Design & Technology Selection

Environmental site survey and RF propagation analysis with integration architecture design

Key Deliverables:- Site survey

- Architecture design

- Technology selection

Pilot Implementation & Validation

Infrastructure deployment and Digital Twin integration with performance testing

Key Deliverables:- Pilot deployment

- Performance testing

- Validation results

Scale-Up Planning & Preparation

Enterprise scaling strategy and resource planning with change management preparation

Key Deliverables:- Scaling strategy

- Resource planning

- Change management

Enterprise Deployment & Integration

Phased infrastructure rollout with business process integration and workflow automation

Key Deliverables:- Infrastructure rollout

- Process integration

- ROI measurement

ROI Framework for RTLS Digital Twin Platform Solutions

Understand the progressive value creation model that delivers exponential returns through three levels of RTLS Digital Twin implementation, each building upon the last to create compounding business value.

Level 1: Visibility

Transform blind operations into complete spatial awareness with real-time asset and personnel tracking

Key Capabilities:- Real-time location tracking with sub-meter accuracy

- Historical movement analytics and pattern recognition

- Eliminate 80-95% of search time across operations

- Increase asset utilization rates by 25-40%

Level 2: Measure & Control

Leverage predictive analytics and process optimization to prevent issues before they occur

Key Capabilities:- Predictive analytics for bottleneck identification

- Dynamic workflow optimization algorithms

- Predict and prevent 70-90% of operational disruptions

- Optimize resource allocation reducing cycle times 25-35%

Level 3: Planning & Simulation

Achieve autonomous operational optimization through self-learning systems and continuous improvement

Key Capabilities:- AI-powered autonomous optimization engines

- Self-adapting algorithms for changing conditions

- Autonomous operational optimization without human intervention

- Self-adapting systems that improve performance over time

Overcoming RTLS Digital Twin Integration Challenges

Navigate common integration challenges with proven solutions and expert guidance that ensures successful real time digital twin deployment with accurate data and sustained operational value.

Data Synchronization & Latency

Real-time data processing challenges with enterprise systems integration and edge computing solutions for sub-50ms latency.

Accuracy & Environmental Interference

Multi-sensor fusion algorithms combining UWB, BLE, and WiFi technologies to maintain precision in challenging RF environments.

Scalability & Performance

Cloud-native microservices architecture with auto-scaling capabilities to handle 10,000+ tracked assets efficiently.

Enterprise System Integration

Standardized API gateway and integration platform for seamless connectivity with ERP, MES, and WMS systems.

Change Management & Adoption

Comprehensive stakeholder engagement and role-based training programs to ensure high user adoption rates.

Data Privacy & Security

Zero-trust security architecture with end-to-end encryption and compliance monitoring for regulatory adherence.

Asset Tag Lifecycle Management

Automated provisioning, health monitoring, and predictive maintenance systems for optimal tag performance.

ROI Measurement & Justification

Comprehensive KPI frameworks and real-time value tracking systems to demonstrate continuous business impact.

RTLS Digital Twin Success Stories: Real-World Implementations and Results

Explore proven real time digital twin implementations across industries with quantified results and validated ROI through comprehensive case studies and verified industry benchmarks.

German Automotive OEM - Tool Management Excellence

Challenge: 15,000+ specialized tools across 2M sq ft facility with critical tool loss and quality...

Solution: Ultra-Wideband (UWB) infrastructure with 10–30cm...

Key Results:

Top-5 US Health System - Equipment & Patient Flow

Challenge: 800-bed facility with nurses spending 21% of shift time searching for equipment...

Solution: BLE beacons and Wi-Fi based RTLS leveraging...

Key Results:

Global 3PL Provider - Distribution Center Transformation

Challenge: 500,000 sq ft distribution center with 98.5% picking accuracy...

Solution: UWB-based positioning for forklifts and AGVs...

Key Results:

European Steel Manufacturer - Safety in Harsh Environments

Challenge: Extreme industrial environment with temperatures from -20°C to +1200°C, high

Solution: Industrial-grade UWB with mesh networking, intrinsically

Key Results:

Major Aerospace Manufacturer - FOD Prevention & Tool Control

Challenge: Regulatory requirement for 100% tool accountability...

Solution: Ultra-high precision UWB with 10cm accuracy, blockchain...

Key Results:

Industry-Verified Benchmarks

150–250%

Typical 3-Year ROI

Gartner Research 202314–24

Months Payback

ARC Advisory Group20–35%

Asset Utilization Gain

IDC Manufacturing70–90%

Search Time Reduction

McKinsey InstituteFrequently Asked Questions: RTLS Digital Twin Implementation

Get answers to common questions about Digital Twin implementation, benefits, and best practices from our experts who have successfully deployed Digital Twin solutions across various industries.

What's the difference between RTLS Digital Twin and traditional Digital Twin solutions?

Traditional Digital Twins rely on static data and manual updates, creating a delayed representation of reality. RTLS Digital Twins use real-time location data to create living, breathing models that reflect actual operational conditions as they happen. This enables proactive decision-making instead of reactive reporting.

How accurate is RTLS technology, and what factors affect accuracy?

Modern RTLS technologies achieve sub-meter accuracy, with UWB systems reaching 10-30cm precision. Accuracy depends on technology choice, environmental factors, infrastructure design, and calibration. Our site surveys identify potential interference sources and optimize placement for maximum accuracy.

What's the expected ROI and how quickly can we see results?

Enterprise implementations typically take 3-6 months from planning to full deployment. This includes 2-4 weeks for assessment, 4-8 weeks for pilot implementation, and 8-16 weeks for enterprise rollout. Timeline varies based on facility size, complexity, and integration requirements.

How do you ensure data security and privacy in RTLS Digital Twin systems?

We implement comprehensive security frameworks including end-to-end encryption, role-based access controls, secure API gateways, and compliance monitoring. All data transmission and storage follows industry standards like ISO 27001, and we support air-gapped deployments for sensitive environments.

What's the expected ROI and how quickly can we see results?

Typical ROI ranges from 300-600% within 18 months, with initial benefits visible within 30 days. Quick wins include reduced search times and improved asset utilization. Longer-term benefits include process optimization, predictive maintenance, and strategic decision support capabilities.

How does RTLS Digital Twin integrate with existing enterprise systems?

Integration uses standardized APIs and middleware to connect with ERP, MES, WMS, and other enterprise systems. We support both real-time data streaming and batch processing, with pre-built connectors for major platforms like SAP, Oracle, Microsoft, and others.

What happens if the RTLS infrastructure fails or needs maintenance?

Systems include redundancy planning, backup procedures, and graceful degradation modes. Critical operations can continue with reduced functionality while infrastructure is restored. Maintenance windows are planned during low-activity periods.

How do you measure ROI from Digital Twin investments?

ROI is measured through cost savings (reduced maintenance, downtime, energy consumption), revenue enhancement (faster development, new services, improved quality), and risk mitigation (prevented failures, compliance automation). Most organizations see positive ROI within 18-24 months with proper implementation.

How do you validate business value and track ongoing performance?

Validation includes baseline measurement, KPI tracking, and continuous monitoring dashboards. Performance metrics cover operational efficiency, safety compliance, and financial impact with regular reporting and optimization recommendations.

What factors should be considered when scaling from pilot to enterprise deployment?

Scaling considerations include infrastructure capacity, user training programs, change management processes, system performance optimization, and phased rollout planning. Success depends on proven pilot results and stakeholder buy-in.

How do you future-proof RTLS + Digital Twin investments against technology evolution?

Future-proofing strategies include open architecture design, vendor-agnostic platforms, modular system components, and technology roadmap alignment. Regular assessment ensures compatibility with emerging technologies like 5G, AI/ML, and edge computing.

Still have questions?

Schedule a ConsultationThe Continuous Improvement Engine

How RTLS Digital Twins Create Self-Optimizing Operations

Traditional improvement methodologies rely on periodic assessments and manual interventions. RTLS Digital Twins reimagine continuous improvement as an automated, perpetual process operating at the speed of data, not quarterly reviews.

The Four-Stage Perpetual Optimization Cycle

1. Visualize

Real-time visualization creates intuitive understanding of complex operational dynamics impossible to grasp through numbers alone.

2. Measure

Revolutionary measurement captures previously invisible operational dimensions with automated KPI calculation.

3. Simulate

Transform decision-making from educated guessing to scientific prediction. Every operational change tested digitally first.

4. Optimize

Insights transform into actions, generating new data for the next cycle through three levels of optimization hierarchy.

Deep Dive: How Each Stage Works

Key Insights

- Visual info processed 60,000x faster than text

- KPIs generated without manual data entry

- Simulation prevents costly mistakes before deployment

- Human role shifts from manual optimization to strategy

Deep Dive: How Each Stage Works

Visualize

Real-time visualization creates intuitive understanding of complex operational dynamics impossible to grasp through numbers alone.

Key Capabilities:

- 2D/3D facility maps with real-time positions

- Time-series analysis revealing patterns

- Actual vs. designed workflow diagrams

- Asset, people, and process relationships

- Future state projections

Key Insight:

The human brain processes visual information 60,000× faster than text. Operators respond intuitively and immediately to visual bottlenecks.

Measure

Revolutionary measurement captures previously invisible operational dimensions with automated KPI calculation.

Key Capabilities:

- Interaction Analytics: proximity time between assets/operators

- Path Efficiency: actual vs. theoretical minimum distance

- Dwell Time Distribution: statistical wait analysis

- Flow Velocity: movement speed through stages

- Congestion Costs: quantified bottleneck impact

Key Insight:

Hundreds of KPIs calculated automatically without manual entry, including OEE, FTR rates, and resource utilization based on actual presence.

Simulate

Transform decision-making from educated guessing to scientific prediction. Every operational change tested digitally first.

Key Capabilities:

- Flow modeling with current throughput

- Agent-based simulation of individual behavior

- Physics-based digital twin simulation

- Monte Carlo analysis for risk/variability

- Automated continuous scenario testing

Key Insight:

Simulation revealed adding a new product line would reduce throughput by 23% due to shared inspection station — saving $2M in losses.

Optimize

Insights transform into actions, generating new data for the next cycle through three levels of optimization hierarchy.

Key Capabilities:

- Assisted: system recommends, human approves

- Semi-Autonomous: auto-implements approved tasks

- Fully Autonomous: continuous micro-adjustments

- Self-Learning: algorithms improve over time

- Predictive: prevents issues before they occur

Key Insight:

Human role shifts from manual optimization to strategy and constraint setting as the system achieves autonomous operation.

The Compounding Effect: Why Continuous Beats Periodic

Daily Micro-Improvements

0.1% daily efficiency gain compounds to 44% annually

Instant Problem Resolution

Problems identified and resolved in minutes, not months

Organizational Learning

Best practices automatically identified and propagated

Accelerated Onboarding

New employees learn through simulation and codified knowledge

Ready to Build Your Continuous Improvement Engine?

Transform your operations with RTLS Digital Twins that learn, adapt, and optimize automatically — creating compound improvements that accelerate over time.

Discover More About RTLSTraditional Digital Twin vs RTLS Digital Twin

The Fatal Flaws of Traditional Digital Twins

Understanding the fundamental differences and why location intelligence changes everything

The Dangerous Assumption

Traditional digital twins assume the physical world matches the model. In real operations, this breaks down catastrophically, creating digital theater instead of operational intelligence.

Planned vs. Actual Positioning

Traditional: Assets are where WMS says

Reality: 15–30% mislocated

Static vs. Dynamic Behavior

Traditional: Prescribed workflows

Reality: Operators create shortcuts

Theoretical vs. Actual Timing

Traditional: Engineered standards

Reality: ±40% variability

The Five Critical Gaps in Traditional Digital Twins

Gap 1: Temporal Disconnect

Traditional Data Delays:

- Manual entry: 4–24 hrs

- Batch processing: 1–8 hrs

- System sync: 15–60 mins

RTLS Solution:

Gap 2: Spatial Blindness

Case Study – Distribution Center

A traditional twin showed optimal pick paths. The RTLS Digital Twin revealed 40% deviations due to congestion zones.

Result: 25% productivity improvement

Gap 3: Granularity Gulf

Traditional Granularity

- Hourly counts

- Daily utilization

- Weekly quality metrics

- Monthly reports

RTLS Granularity

- Second-by-second updates

- Minute flow analysis

- Real-time interactions

- Instant anomaly detection

Gap 4: Integration Impediment

Traditional Challenges

- Incompatible formats

- Conflicting cycles

- Limited APIs

- Poor data quality

RTLS Advantage

- Single source of truth

- Position-based correlation

- Event-driven architecture

- Self-validating data

Gap 5: Simulation-Reality Chasm

Why Traditional Fails

- Theoretical models only

- No human factors

- No environment data

- No outcome validation

RTLS Simulation Accuracy

- Millions of datapoints

- Human patterns included

- Environment monitored

- Auto-calibrated from outcomes

The Hidden Costs of Inadequate Digital Twins

Direct Costs

- Manual data collection

- Simulation re-validation

- Frequent recalibration

- Limited ROI

Opportunity Costs

- Delayed issue detection

- Missed optimizations

- Slow innovation

- Competitive disadvantage

Risk Costs

- Inaccurate decisions

- Compliance issues

- Safety incidents

- Customer impacts

The Transformation: From Digital Theater to Operational Intelligence

Traditional Twin

- ❌ Wrong visualizations

- ❌ Historical, not real-time

- ❌ Unvalidated simulations

- ❌ Quarterly improvements

RTLS Digital Twin

- ✅ Mirrors reality in cm accuracy

- ✅ Predictive, prevents issues

- ✅ Validated by millions of data points

- ✅ Continuous optimization

Ready to Experience the RTLS Advantage?

Transform your digital twin from passive reporting into an intelligent, predictive, self-optimizing system.

Learn More About Digital TwinsRTLS Digital Twin Maturity Journey

A comprehensive guide to the three levels of RTLS Digital Twin implementation, from foundational visibility to autonomous operational intelligence.

Level 1

Real-Time Visibility

Level 2

Measure & Control

Level 3

Planning & Simulation

Level 1 – Real-Time Visibility 4–8 weeks pilot, 3–4 months rollout

The Foundation of Spatial Intelligence

Transform operations from assumption-based to evidence-based decision making with complete spatial awareness.

Core Capabilities

Instant Location Intelligence

- Locate any tagged asset within seconds

- Real-time position updates every 1–10 seconds

- Historical location playback

- Geofence alerts for violations

Live Operational Overview

- Unified facility-wide dashboard

- Heat maps showing traffic patterns

- Real-time occupancy metrics

- Mobile applications for staff

Industry Applications

Manufacturing

- Tool tracking across production floors

- WIP visibility through stages

- Mobile asset utilization

- Critical component location

Healthcare

- Medical equipment tracking

- Staff duress monitoring

- Patient flow visualization

- Asset PAR level management

Logistics

- Yard management & trailer tracking

- Cross-dock operations visibility

- Material handling equipment

- Inventory zone management

Expected Outcomes

- Search time: 30+ minutes → under 30 seconds

- Asset utilization improvement: 15–25%

- Inventory accuracy: 99%+

- Immediate ROI through found assets

Level 2 – Measure & Control 2–4 months implementation

Transforming Data into Operational Intelligence

Transcend simple tracking to deliver deep operational insights through spatial analytics and predictive intelligence.

Core Capabilities

Spatial Process Mining

- Spaghetti diagrams actual vs planned

- Bottleneck identification

- Distance optimization

- Process deviation detection

Predictive Intelligence

- Queue time predictions

- Usage-based maintenance

- Demand forecasting

- Anomaly detection

Automated Control Systems

- Dynamic work assignment

- Automatic SLA escalation

- Occupancy-based control

- AGV collision avoidance

Key Insights Revealed

Movement analytics consistently reveal:

- 30–40% of handler movement = empty travel

- 15–20% of nursing shifts lost to equipment search

- Cross-contamination risks from paths

- Overtime correlates with bottlenecks

Expected Outcomes

- Process efficiency +25–35%

- Labor productivity +20–30%

- Compliance-driven quality improvements

- Predictive downtime reduction 15–20%

Level 3 – Planning & Simulation 6–12 months full implementation

Autonomous Operational Intelligence

Enable organizations to simulate changes before implementation and create self-improving systems that adapt autonomously.

Core Capabilities

Digital Experimentation

- Test layout changes

- Simulate product impact

- Model staffing scenarios

- Validate process changes

What-If Analysis

- Production line impact

- Relocation simulations

- Equipment optimization

- Multi-variable testing

Autonomous Optimization

- Dynamic slotting

- Automatic work queue rebalancing

- Self-adjusting safety zones

- Predictive dispatching

Continuous Learning

- Optimal path learning

- Failure mode prediction

- Pattern-based process improvements

- Seasonal variation adaptation

Expected Outcomes

- Autonomous operations

- Risk-quantified decision support

- Innovation via prototyping

- Competitive advantage through agility

- New business models

Ready to Begin Your RTLS Digital Twin Journey?

Each maturity level builds upon the previous, creating exponential value. Start with Level 1 and evolve toward autonomy.

Get Expert Real-Time Digital Twin ConsultationBuilding Blocks of RTLS Digital Twins

The Five-Layer Architecture That Powers Autonomous Operations

Integrated Architecture Advantage

Creating an RTLS Digital Twin requires more than just combining location tracking with simulation software. It demands a carefully orchestrated architecture where each layer serves a specific purpose while seamlessly integrating with others to create operational intelligence that’s greater than the sum of its parts.

Layer 1 Physical Reality Layer

The Spatial Foundation

Forms the sensory nervous system of your digital twin, capturing every movement, interaction, and environmental condition across operations.

Key Capabilities

- Ultra-Wideband (UWB): 10–30cm accuracy, 100Hz updates

- Bluetooth Low Energy (BLE): 1–5cm accuracy, improving with AoA/AoD

- Active RFID Systems: Zone-based tracking up to 100m

- Environmental sensors with spatial correlation

- Industrial-grade multi-tech asset tags

Technical Specifications

- Infrastructure Density: 1 anchor per 400–1000 sq m

- Battery Life: 1–7 years (depending on tech)

- Update Rates: Up to 100Hz for critical apps

- Environmental Monitoring: Temp, humidity, vibration, air quality

Layer 2 Real-Time Data Fusion Layer

The Intelligence Pipeline

Transforms millions of position updates into actionable intelligence through advanced processing and AI-powered analytics.

Key Capabilities

- Sub-100ms latency for critical decisions

- 90% bandwidth reduction via filtering

- Kalman filtering for precision enhancement

- Multi-sensor fusion algorithms

- Context-aware validation

Technical Specifications

- Processing Volume: 80M+ position records daily (1000 assets)

- Edge Processing: Real-time detection & response

- Cloud Processing: ML model training

- Hybrid Architecture: Edge + cloud blend

Layer 3 Digital Twin Modeling Layer

The Virtual Operations Center

Creates living, breathing digital representations that mirror and predict physical reality through 4D spatial models.

Key Capabilities

- 4D Spatial Models (3D + Time) with replay

- Physics-based simulation engines

- Discrete Event Simulation (DES)

- Agent-Based Modeling (ABM)

- Multi-objective optimization algorithms

Technical Specifications

- Model Fidelity: From geometric to physics-enabled

- Simulation Types: DES, ABM, continuous

- Optimization: Real-time constraint programming

- Temporal Analysis: Replay at any speed

Layer 4 Location Intelligence Analytics Layer

The Insight Engine

Transforms data into decisions through advanced analytics powered by spatial context and predictive modeling.

Key Capabilities

- Spatial metrics: Distance, proximity, zone analytics

- Predictive modeling from seconds to months ahead

- Autonomous anomaly detection

- Multi-dimensional pattern recognition

- Behavioral optimization recommendations

Technical Specifications

- Short-term Predictions: Collisions, queues

- Medium-term Predictions: Demand, scheduling

- Long-term Predictions: Capacity, layouts

- Anomaly Types: Spatial, temporal, behavioral, contextual

Layer 5 Autonomous Control & Interface Layer

The Action Layer

Where insights become actions through real-time control systems and human-machine collaboration.

Key Capabilities

- Closed-loop control with fail-safe

- AGV/AMR fleet dynamic path planning

- Environmental controls from occupancy

- Production optimization control

- Role-based dashboards

Technical Specifications

- Automation Levels: Manual → full autonomous

- Integration: AGV, HVAC, lighting, production

- Interface: Operator, supervisor, executive

- Response: Automated optimization & self-healing

Emergent Capabilities When Layers Work Together

System detects and corrects issues automatically before they impact operations

Changes made before problems occur through advanced forecasting

Continuous improvement without programming through AI-powered insights

Automation Maturity Journey

- 0 Level 0: Manual Control – Humans decide, system provides info only

- 1 Level 1: Decision Support – System recommends, humans approve

- 2 Level 2: Supervised Automation – System executes, humans handle exceptions

- 3 Level 3: Conditional Automation – Complex cases handled, humans set policies

- 4 Level 4: High Automation – System operates independently, humans monitor

- 5 Level 5: Full Automation – Self-optimizing, humans focus on innovation

Ready to Build Your RTLS Digital Twin?

Unlock operational intelligence with a layered architecture that evolves from tracking to autonomous optimization.

Avail RTLS + Digital Twin Integration ServicesManufacturing RTLS Digital Twin Implementation

Transform your production floor through three progressive stages: from reactive visibility to predictive intelligence to autonomous optimization.

Stage 1: The Visibility Twin

Your Live Factory Floor

Core Concept

Illuminate your entire production environment with real-time visibility. Every critical mobile equipment, high-value tool, WIP pallet, and AGV appear on a single dynamic map—eliminating manual scans, paper trails, and wasted searches.

Real Manufacturing Scenario

The Problem: Production line goes down. Missing test jig? Sub-assembly stuck? Operator unavailable?

The Solution: Instead of frantic investigation, you see it all instantly: jig in calibration lab, sub-assembly two minutes away, operator assisting nearby. A 30-minute crisis solved in seconds.

Instantly locate any critical asset—from tools and test equipment to MHE and WIP

Find the root cause of stoppages instantly, eliminating costly production delays

Reduce wasted motion for operators and supervisors with a single source of truth

Gain complete situational awareness of your entire shop floor, all the time

Stage 2: The Measure & Control Twin

From Data to Production Intelligence

Core Concept

With a foundation of live visibility, your Digital Twin now becomes an analytical powerhouse. It doesn't just show you where things are; it shows you how they interact and perform over time. It contextualizes location data, revealing the hidden inefficiencies in your workflows, material flow, and resource utilization.

Real Manufacturing Scenario

The Problem: Your Digital Twin visualizes the "spaghetti diagram" of your material handlers, but goes deeper. It reveals that 40% of all forklift and AGV travel is "empty runs."

The Solution: By correlating the dwell time of WIP pallets at specific work cells with the OEE of those machines, it proves that Cell 5 is consistently starved for components between 2-4 PM, causing hidden micro-stoppages that kill your efficiency. This isn't just a map; it's a deep diagnostic of your entire value stream.

Optimize material flow by identifying and eliminating inefficient routes and empty runs.

Uncover the root causes of production bottlenecks by correlating asset movement with performance data.

Validate and supercharge your lean initiatives with objective, undeniable data.

Improve Overall Equipment Effectiveness (OEE) by ensuring assets, tools, and materials are always where they need to be.

Stage 3: The Planning & Simulation Twin

Engineer Your Future Production, Virtually

Core Concept

This is where your smart factory becomes a strategic weapon. Your Digital Twin evolves into a perfect virtual replica of your production environment, fed by your actual, real-world operational data. It becomes a risk-free sandbox to test, validate, and optimize any change before investing a single dollar or disrupting the floor.

Real Manufacturing Scenario

The Problem: Management wants to introduce a new product line into your existing facility. Where does the new cell go? How will it impact the flow of existing materials and the demand on shared resources?

The Solution: Using the Simulation Twin, you model three potential layouts. You simulate the new MHE routes, the strain on shared forklifts, and the required buffer sizes for both new and existing lines. The simulation proves that the most "obvious" location would create a massive bottleneck, while a less intuitive spot, combined with a small change in AGV logic, allows for seamless integration and even improves the efficiency of an existing line by 10%.

Test new line layouts and process flows without stopping production for a single minute.

Accurately predict the impact of any change on throughput, cycle time, and resource utilization.

Optimize resource allocation—from machinery to staff—for complex production mixes.

De-risk multi-million dollar capital investments by proving their ROI in a virtual environment first.

Ready to Transform Your Manufacturing?

From real-time visibility to predictive intelligence, accelerate production efficiency with RTLS Digital Twins.

Explore Real-Time Digital Twin in ManufacturingHealthcare RTLS Digital Twin Implementation

Transform your hospital through three progressive stages: from reactive visibility to predictive intelligence to autonomous optimization.

Stage 1: The Visibility Twin

Your Live Hospital Environment

Core Concept

Create a single source of truth for your entire facility. Move beyond systems and whiteboards to a live, dynamic hospital map where every critical asset, staff, and patient location is visible in real-time.

Healthcare Scenario

The Problem: A “code blue” is called on the cardiac floor. The charge nurse needs the nearest crash cart, the cardiologist, and an ICU bed—immediately.

The Solution: Instead of frantic phone calls, a glance at the Visibility Twin shows the nearest cart is one room over, locates the cardiologist in the adjacent wing, and confirms ICU Bed 4 is prepped and ready. A life-threatening delay becomes a coordinated, instantaneous response.

Locate critical medical equipment, reducing search times from minutes to seconds

Real-time visibility into bed status and patient location

Understanding where clinicians are and deploying them effectively

Improve patient safety and satisfaction through faster response times

Stage 2: The Measure & Control Twin

From Data to Clinical Intelligence

Core Concept

The Digital Twin becomes a process improvement engine. It tracks patient, staff, and equipment interactions over time, uncovering bottlenecks and inefficiencies in workflows.

Healthcare Scenario

The Problem: Hospital administrators are tackling long Emergency Department wait times.

The Solution: The Digital Twin analyzes the entire patient journey and reveals that the primary bottleneck isn't bed availability, but a consistent 90-minute delay in patient transport to radiology. It also shows 30% of the wheelchair fleet is clustered, unused, on one floor. This intelligence enables targeted fixes—revising transport workflows and rebalancing mobile assets—slashing ED wait times.

Drastically reduce patient wait times by identifying and resolving workflow bottlenecks

Maximize utilization of high-value equipment like IV pumps and telemetry monitors

Streamline patient discharge and room cleaning processes

Analyze movement patterns and eliminate wasted steps

Stage 3: The Planning & Simulation Twin

Design the Future of Care, Virtually

Core Concept

Your Digital Twin evolves into a perfect virtual replica of your facility, powered by your own real-world data. It becomes a risk-free environment to model, test, and validate any operational or physical change before committing resources.

Healthcare Scenario

The Problem: The hospital is planning a new infectious disease wing. How will the layout impact staff exposure risk? What's the most efficient layout for nurse travel paths and supply delivery?

The Solution: Using the Simulation Twin, planners model different room configurations and workflows. They simulate patient surge scenarios to test staffing models and resource needs, ensuring the new wing is both safe and hyper-efficient from day one, all before the first wall is built.

Optimize new construction or departmental renovations before breaking ground

Refine clinical protocols and patient flow strategies in a virtual environment

Develop robust emergency plans by simulating patient surge events

Match predicted patient demand with data-driven confidence

Ready to Transform Your Healthcare Facility?

From visibility to predictive intelligence, accelerate care delivery with RTLS Digital Twins.

Explore Real-Time Digital Twin in HealthcareLogistics RTLS Digital Twin Implementation

Transform your warehouse and distribution operations through three progressive stages: from reactive visibility to predictive intelligence to autonomous optimization.

Stage 1: The Visibility Twin

Your Live Warehouse & Yard

Core Concept

The journey starts by eliminating the black holes in your operation. Forget manual check-ins and system-only inventory locations. This is your entire facility—every forklift, every pallet jack, every high-value shipment, and every worker—visualized on a single, dynamic map that covers the yard, the dock doors, and the warehouse floor in real-time.

Real-World Scenario

The Problem: A truck carrying a high-priority inbound shipment arrives an hour early. Meanwhile, a picker on the floor cannot find a specific pallet for a critical outbound order, threatening to miss a delivery SLA.

The Solution: A glance at the Visibility Twin shows the early truck in the yard and an open dock door it can be assigned to. It also pinpoints the “missing” pallet, mistakenly placed in a bulk storage aisle. A potential domino effect of delays is resolved in seconds.

All assets, from trucks in the yard to pallets on the floor

For inventory, MHE, and personnel

Reduce driver detention fees

Prevent costly shipping errors

Stage 2: The Measure & Control Twin

From Data to Fulfillment Intelligence

Core Concept

With total visibility established, your Digital Twin becomes your operational analyst. It contextualizes location data to uncover bottlenecks in receiving, putaway, picking, and shipping processes.

Real-World Scenario

The Problem: Your WMS reports good overall performance, but you’re still missing SLAs.

The Solution: Your Digital Twin visualizes the "spaghetti diagram" of your forklift fleet, revealing chaotic, overlapping routes and that 30% of all travel is "empty forks." By analyzing the dwell time of pallets from dock-to-stock, it proves your receiving process is creating downstream inventory shortages for your pickers, forcing them to wait. This is the root cause of your missed SLAs.

Increase lines picked per hour

Dock-to-stock and stock-to-dock

In aisles and staging areas

MHE movement analysis and compliance

Stage 3: The Planning & Simulation Twin

Engineer Your Future Warehouse, Virtually

Core Concept

This is where your warehouse becomes a strategic advantage. Your Digital Twin evolves into a perfect virtual replica of your facility and its processes, fed by your actual, real-world operational data. It becomes a risk-free sandbox to test any change—from a new racking layout to a completely different picking strategy—before disrupting the floor.

Real-World Scenario

The Problem: You’re preparing for a 40% surge during peak season. How many temps do you need? Invest in more pallet jacks?

The Solution: Using the Simulation Twin, you model the impact of the surge on your current operation. You then test various strategies: implementing a wave picking process, creating a forward-pick zone for high-velocity items, and changing the slotting for seasonal SKUs. The simulation proves that a dynamic forward-pick zone can handle the surge with only a 15% increase in labor, saving six figures in seasonal hiring costs.

Model seasonal surges and optimize resource allocation

Test new racking configurations and slotting strategies

Reduce labor costs through optimized workflows and automation

Test new fulfillment strategies before implementation

Ready to Transform Your Logistics?

From real-time visibility to predictive intelligence, accelerate fulfillment with RTLS Digital Twins.

Explore Real-Time Digital Twin in LogisticsRTLS Digital Twin Implementation Framework

Comprehensive six-phase methodology for successful deployment and sustained value realization

Core Implementation Principles

- Risk-first implementation strategy with comprehensive mitigation planning

- Continuous stakeholder engagement and transparent communication

- Iterative validation and refinement based on real-world feedback

- Change management integration throughout all phases

- Data-driven decision making with measurable success criteria

- Scalable architecture design for future growth and expansion

Critical Success Factors

- Executive sponsorship with clear vision and committed resources

- Cross-functional implementation team with diverse expertise

- Comprehensive site survey and environmental analysis

- Robust integration architecture with API-first design

- User-centric design with extensive training and support

- Continuous performance monitoring and optimization

Strategic Assessment & Use Case Definition

Comprehensive current state analysis and location intelligence audit with strategic use case prioritization and ROI projections

Key Activities

- Operational workflow analysis and pain point identification

- Asset tracking requirements assessment and gap analysis

- Stakeholder interviews and cross-functional needs analysis

- Use case prioritization matrix development with ROI weighting

- Business case creation with 3-year financial projections

- Technology readiness assessment and infrastructure audit

- Competitive analysis and market positioning evaluation

Key Deliverables

- Current state assessment report with detailed findings

- Prioritized use case roadmap with implementation sequence

- Success metrics framework with KPI definitions

- Business case and ROI projections with sensitivity analysis

- Stakeholder engagement plan and communication strategy

- Risk assessment matrix with mitigation strategies

Critical Success Factor

Executive alignment on strategic objectives, clear success metrics, and committed budget allocation

Architecture Design & Technology Selection

Comprehensive environmental site survey and RF propagation analysis with scalable integration architecture design

Key Activities

- RF site survey and propagation modeling with heat mapping

- Technology stack evaluation including UWB, BLE, WiFi, and hybrid approaches

- Integration architecture design with API specifications

- Security framework development with zero-trust principles

- Scalability planning and future-proofing assessment

- Data governance framework establishment

- Performance benchmarking and SLA definition

- Vendor evaluation and technology partner selection

Key Deliverables

- Detailed site survey report with RF propagation models

- Technology selection rationale with comparative analysis

- System architecture blueprint with integration points

- Security architecture with compliance framework

- API specifications and data flow diagrams

- Scalability roadmap with capacity planning

- Vendor selection report with contract recommendations

Critical Success Factor

Robust, scalable architecture that integrates seamlessly with existing systems and supports future growth

Key Considerations

- Consider multi-technology approach for optimal coverage and redundancy

- Design for interoperability with existing enterprise systems

- Plan for data sovereignty and regulatory compliance requirements

- Ensure architecture supports real-time and batch processing needs

Common Pitfalls to Avoid

- Over-engineering the initial solution

- Insufficient consideration of environmental factors

- Inadequate security planning from the outset

Pilot Implementation & Validation

Controlled pilot deployment with Digital Twin integration and comprehensive performance validation

Key Activities

- Infrastructure deployment in controlled pilot environment

- Digital Twin model development with physical-based simulation

- System integration testing with existing enterprise systems

- User acceptance testing with representative user groups

- Performance benchmarking against defined KPIs

- Data quality validation and accuracy assessment

- User experience optimization and interface refinement

- Operational procedures development and documentation

Key Deliverables

- Functional pilot system with full feature set

- Performance validation report with benchmark metrics

- User feedback analysis with improvement recommendations

- Data quality assessment with accuracy metrics

- Operational procedures documentation

- Training materials and user guides

- Optimization recommendations for full deployment

Critical Success Factor

Proven system performance exceeding baseline metrics and positive user adoption in controlled environment

Key Considerations

- Specify clear scope and expected outcomes of broader operational environment

- Establish clear success criteria before pilot begins

- Involve end-user stakeholders throughout pilot process

- Document all lessons learned for full deployment

Common Pitfalls to Avoid

- Choosing non-representative pilot environment

- Inadequate training and user support

- Insufficient performance monitoring during pilot

Scale-Up Planning & Preparation

Enterprise scaling strategy development with comprehensive resource planning and change management preparation

Key Activities

- Enterprise scaling strategy development with phased approach

- Resource allocation planning including personnel and budget

- Change management program design with communication strategy

- Training curriculum development for different user roles

- Support structure establishment with help desk and escalation procedures

- Performance monitoring framework setup

- Risk mitigation planning with contingency procedures

- Success metrics refinement based on pilot results

Key Deliverables

- Enterprise scaling strategy with detailed timelines

- Resource allocation plan with budget breakdown

- Change management framework with communication plan

- Comprehensive training materials and certification programs

- Support structure documentation with escalation procedures

- Performance monitoring dashboard specifications

- Risk mitigation plan with contingency procedures

Critical Success Factor

Comprehensive preparation ensuring smooth enterprise-wide deployment with minimal business disruption

Key Considerations

- Plan for gradual rollout to minimize operational risk

- Establish clear communication channels for all stakeholders

- Prepare for increased support requirements during initial rollout

- Create feedback loops for continuous improvement

Common Pitfalls to Avoid

- Underestimating training and support requirements

- Ineffective change management preparation

- Inadequate resource allocation for full deployment

Enterprise Deployment & Integration

Phased infrastructure rollout with business process integration and comprehensive workflow automation

Key Activities

- Phased infrastructure deployment across enterprise locations

- Business process integration with workflow automation

- User training and onboarding with role-specific programs

- Performance monitoring and optimization

- Data migration and historical data integration

- Third-party system integration and API connections

- Compliance validation and audit preparation

- Go-live support and stabilization activities

Key Deliverables

- Enterprise-wide infrastructure with full coverage

- Integrated business processes with automated workflows

- Trained and certified user base across all roles

- Performance monitoring dashboard with real-time metrics

- Integrated data ecosystem with historical context

- Compliance documentation and audit reports

- Go-live support documentation and procedures

Critical Success Factor

Seamless integration with existing operations, high user adoption rates, and measurable business impact

Key Considerations

- Maintain business continuity throughout deployment

- Monitor performance closely during post-go-live period

- Provide continuous user training and support as needed

- Continuously analyze data to maintain relevance and engagement

Common Pitfalls to Avoid

- Rushing deployment without adequate testing

- Insufficient go-live support and user assistance

- Poor communication during transition periods

Optimization & Continuous Improvement

Continuous performance analytics and improvement identification with strategic use case expansion planning

Key Activities

- Performance analytics and KPI monitoring with trend analysis

- Continuous optimization initiatives based on data insights

- Use case expansion planning with ROI evaluation framework

- Best practice documentation and knowledge sharing

- Innovation roadmap development with emerging technology assessment

- User feedback collection and system enhancement

- Advanced analytics implementation with AI/ML capabilities

- Strategic planning for next-generation capabilities

Key Deliverables

- Performance analytics dashboard with predictive insights

- Continuous optimization recommendations and implementation

- Expanded use case implementations with measured ROI

- Best practice documentation and training updates

- Innovation roadmap with technology evolution plan

- Advanced analytics capabilities with AI/ML integration

- Strategic plan for next-generation digital twin capabilities

Critical Success Factor

Sustained value realization, continuous innovation culture, and strategic competitive advantage

Key Considerations

- Establish regular review cycles for performance and optimization

- Maintain focus on business value and ROI measurement

- Foster culture of continuous improvement and innovation

- Stay current with emerging technologies and industry trends

Common Pitfalls to Avoid

- Treating implementation as one-time project rather than ongoing journey

- Insufficient investment in continuous improvement

- Losing focus on business outcomes and user needs

Risk Mitigation and Contingency Planning

Technical Risks

RF Interference Issues

Impact: High Probability: MediumMitigation: Comprehensive site survey, multi-technology approach with UWB, BLE, WiFi redundancy, adaptive algorithms

Contingency: Alternative technology deployment, phased rollout

Integration Complexity

Impact: High Probability: MediumMitigation: API-first design, extensive integration testing

Contingency: Simplified staging, dedicated integration team

Scalability Limitations

Impact: Medium Probability: LowMitigation: Cloud-native architecture, modular system

Contingency: Infrastructure scaling, performance optimization

Data Quality Issues

Impact: High Probability: MediumMitigation: Validation framework, real-time monitoring

Contingency: Sensor deployment, quality improvement initiatives

Operational Risks

User Adoption Challenges

Impact: High Probability: MediumMitigation: Training programs, change champions, feedback integration

Contingency: Incentive programs, additional support resources

Performance Expectations Gap

Impact: Medium Probability: MediumMitigation: Clear KPIs, continuous optimization

Contingency: Adjustment of scope, stakeholder engagement

Budget Overruns

Impact: High Probability: LowMitigation: Detailed cost planning, phased rollout

Contingency: Scope reduction, additional budget approval

Timeline Delays

Impact: Medium Probability: MediumMitigation: Realistic milestone planning, resource reallocation

Contingency: Parallel work streams, extended timelines

Typical Implementation Timeline & Milestones

Foundation Phase

- Stakeholder alignment

- Architecture design completion

- Pilot deployment success

Deployment Phase

- Enterprise-wide deployment

- System integration complete

- User training completion

Optimization Phase

- 100% coverage achieved

- Advanced analytics deployment

- Continuous improvement cycle

RTLS Digital Twin Implementation Guide

Explore RTLS + Digital Twin ImplementationROI Calculation Framework for RTLS Digital Twins

Comprehensive methodology for quantifying value creation across operational, strategic, and transformational dimensions

Three-Dimensional Value Creation Model

Operational Value

- Labor productivity improvement: 15–35%

- Asset utilization optimization: 20–40%

- Search time elimination: 80–95%

- Operational overhead reduction: 10–25%

- Quality defect reduction: 30–60%

Strategic Value

- Process optimization insights

- Predictive maintenance capabilities

- Data-driven decision making

- Customer satisfaction improvement

- Regulatory compliance automation

Transformational Value

- New revenue stream creation

- Market differentiation capabilities

- Innovation platform foundation

- Ecosystem partnership opportunities

- Future-ready infrastructure

ROI Calculation Components

Cost Reduction Categories

Revenue Enhancement Opportunities

Ready to Calculate Your ROI?

Get a personalized ROI analysis based on your specific operational requirements

Calculate your Digital Twin ROIComprehensive ROI Calculation Methodology

ROI = (Total Benefits - Total Costs - Opportunity Costs) / (Total Costs + Opportunity Costs) × 100%

Opportunity Cost Components

- Delayed efficiency gains: $50K–200K per quarter

- Competitive disadvantage: 5–15% market share risk

- Technology debt accumulation: $25K–100K annually

- Regulatory compliance gaps: $10K–500K potential penalties

Step 1: Quantify Total Costs (per 100K sqft)

Step 2: Calculate Total Benefits

Typical payback for visibility-focused implementations

Advanced analytics and optimization features

Full autonomous optimization systems

Ready to Calculate Your ROI?

Get a personalized ROI analysis based on your specific operational requirements

Calculate your Digital Twin ROIIndustry ROI Benchmarks & Case Studies

Manufacturing

150–250%

3-Year ROI Range

18–24 months

Payback Period

- Tool tracking

- WIP optimization

- Quality control

- Maintenance scheduling

Boeing reduced tool search time by 90% across 17 facilities, saving $2.1M annually with 22-month payback

(Source: Industry Week, 2023)

Healthcare

200–400%

3-Year ROI Range

9–18 months

Payback Period

- Asset tracking

- Patient flow

- Staff optimization

- Compliance monitoring

Mayo Clinic achieved $1.8M annual savings through 85% reduction in equipment search time and 40% improvement in asset utilization

(Source: HFMA, 2023)

Logistics

180–350%

3-Year ROI Range

12–24 months

Payback Period

- Inventory tracking

- Route optimization

- Throughput improvement

- Loss prevention

DHL increased warehouse throughput 28% while reducing labor costs 15% and inventory shrinkage 75%

(Source: SCMR, 2023)

ROI Progression Timeline

Quick Wins

- Asset visibility: 90%+

- Search time reduction: 80%

- Initial ROI: 25–50%

Process Optimization

- Workflow efficiency: +30%

- Quality improvements: +40%

- Cumulative ROI: 75–150%

Advanced Analytics

- Predictive insights

- Autonomous optimization

- Cumulative ROI: 150–250%

Strategic Value

- New revenue streams

- Market differentiation

- Total ROI: 200–400%

Ready to Calculate Your ROI?

Get a personalized ROI analysis based on your specific operational requirements

Calculate your Digital Twin ROIInteractive ROI Calculator

Operational Inputs

Projected Results

Calculation Breakdown

- Search Time Savings: $625,000

- Pallet Handling Savings: $625,000

- WIP Reduction: $1,875,000

- Asset Utilization Gain: $125,000

- Quality Savings: $1,250,000

- Maintenance Savings: $10,000

Ready to Calculate Your ROI?

Get a personalized ROI analysis based on your specific operational requirements

Calculate your Digital Twin ROIOvercoming RTLS Digital Twin Integration Challenges

Practical solutions to common implementation obstacles based on 100+ deployments

Primary failure factors: Integration complexity (34%), Change management (28%), Unrealistic expectations (21%), Technical issues (17%)

Data Synchronization and Latency Management

RTLS updates 10x/second, ERP updates hourly – creating coherent real-time view is complex.

Impact: Total stack latency often 500ms–2s. AGVs at 2m/s move 4 meters during delay → collision warnings arrive too late.

Deploy three-tier processing: Edge (<100ms) for position calculation and collision detection, Fog (100ms-1s) for area coordination, Cloud (1s+) for analytics and BI.

Implementation Approach:

- Deploy edge nodes every 100–200 meters with local processing

- Implement NTP/PTP for microsecond-level synchronization

- Use message queues (MQTT, Kafka) for async processing

- Apply QoS policies ensuring data takes precedence

- Implement local buffering during connectivity issues

Automotive manufacturer reduced collision warning latency from 1.8s to 120ms, preventing 3 near-miss incidents in first month.

Results: Latency reduction 93%, Critical alert response <100ms, System availability 99.9%

Accuracy Degradation in Industrial Environments

Metal structures and EMI significantly impact accuracy.

Impact: Open space: ±10–30cm → Near metal: ±50–150cm → Between racks: ±100–300cm → Signal loss zones.

Combine UWB, BLE, IMU, and computer vision with Kalman/Particle filters. Use ML to learn environment-specific error patterns and predict interference periods.

Implementation Approach:

- Deploy hybrid positioning (UWB + BLE/IMU)

- Implement Extended Kalman Filter for fusion

- Use ML models for interference prediction

- Overlapping coverage with N+1 redundancy

- Map-constrained positioning algorithms

Steel mill achieved 95% position availability with ±1cm accuracy despite heavy EMI.

Results: Accuracy +75%, Dead zone elimination 90%

Enterprise System Integration Complexity

Modern facilities run 15-50 different software systems with diverse protocols, data models, and integration patterns

Impact: Protocol diversity (REST, SOAP, OPC-UA, proprietary), data model mismatches, conflicting ID schemes create integration maze

Implement enterprise service bus with protocol translation, data transformation, and master data management. Use event-driven architecture for loose coupling.

Implementation Approach:

- Deploy API gateway with authentication and rate limiting

- Implement adapter layer for each target system

- Use master data management for ID correlation

- Apply event-driven integration patterns

- Implement federated queries for real-time aggregation

Manufacturing facility integrated 23 systems in 8 weeks vs. typical 6-month timeline using unified integration platform

Results: Integration time: 80% reduction, Data consistency: 99.5%, System coupling: Reduced by 70%

Scalability and Performance Bottlenecks

1,000 assets × 10 updates/second = 864M records/day. Historical data accumulates at 1TB/month with exponential computational demands

Impact: System performance degrades significantly beyond 1,000 tracked assets. Real-time processing becomes impossible at scale

Containerized microservices with Kubernetes orchestration, horizontal scaling, distributed caching, and GPU acceleration for physics simulation.

Implementation Approach:

- Containerize services using Docker/Kubernetes

- Implement horizontal pod autoscaling policies

- Deploy distributed caching (Redis Cluster)

- Use service mesh (Istio) for traffic management

- Implement tiered storage (hot/warm/cold data)

Logistics provider scaled from 100 to 5,000 assets maintaining sub-200ms response times at 50,000 updates/second

Results: Scalability: 50x improvement, Response time: <100ms at scale, Cost efficiency: 60% reduction

Organizational Implementation Challenges

People, process, and cultural transformation obstacles

Change Management and User Adoption

Key Statistics: 78% cite privacy concerns, 94% adoption rate achievable with proper approach

Challenge DetailsBusiness Impact: Poor adoption leads to system underutilization, resistance to process changes, incomplete data collection

- Executive sponsorship from operations leadership

- Union/worker council early engagement and collaboration

- Privacy framework with anonymous tracking where possible

- Champion program with operational and power user tiers

- Multi-modal training (hands-on, video, mobile guides)

Healthcare system achieved 94% adoption by involving nurses in design, implementing privacy protections, focusing on 'time-saving' messaging

Timeline: 3-6 months for full organizational adoption

Data Privacy and Security Requirements

Key Statistics: Regulatory violations average $4M+ annually, GDPR fines up to 4% of revenue

Challenge DetailsBusiness Impact: Legal liability, regulatory fines, worker trust erosion, operational restrictions

- End-to-end encryption (AES-256) for all data transmission

- Role-based access control with multi-factor authentication

- Comprehensive audit logging and compliance monitoring

- Data minimization and automatic expiration policies

- Regular security assessments and penetration testing

Manufacturing facility implemented zero-trust architecture, passed GDPR audit with zero findings, reduced security incidents by 85%

Timeline: 2-4 months for full security implementation

Managing Expectations and Demonstrating ROI

Key Statistics: 60% struggle to quantify value, unrealistic expectations cause 21% of project failures

Challenge DetailsBusiness Impact: Stakeholder disappointment, budget cuts, project cancellation, reduced future investment

- Baseline establishment with time-motion studies

- KPI definition matrix across visibility/control/optimization levels

- Monthly value assessments with executive reporting

- Quick wins identification (months 1-3)

- Long-term transformation roadmap (months 10-18)

Logistics provider demonstrated 15% efficiency gains in month 2, achieved full ROI in 16 months vs. projected 24 months

Timeline: Ongoing with monthly value assessments

Environmental and Operational Challenges

Physical deployment and maintenance obstacles

Asset Tag Management at Scale

Managing thousands of tags becomes significant operational undertaking

Common Problems- Battery replacement scheduling for 5,000+ tags

- Firmware updates across distributed infrastructure

- Tag-asset association maintenance

- Damage/loss tracking and replacement

- Performance monitoring and optimization

- Automated registration and asset association

- Predictive battery replacement algorithms

- Over-the-air firmware update capability

- Real-time performance monitoring dashboards

- Automated spare inventory management (10-15% buffer)

Operational overhead reduction: 60%, Tag uptime: 99.5%, Maintenance cost reduction: 40%

RF Site Design and Optimization

Achieving reliable RTLS coverage requires careful RF engineering in complex industrial environments

Common Problems- Multipath interference from metal structures

- Dynamic environmental conditions affecting signal

- Optimal anchor placement for coverage and accuracy

- Interference from industrial equipment

- Ongoing optimization as facility layout changes

- Comprehensive RF site survey (predictive + active + passive)

- Anchor placement optimization (4-8m height, N+1 coverage)

- Quarterly coverage audits and dead zone detection

- Dynamic power adjustment and interference mitigation

- Automated anchor health monitoring and alerting

Coverage reliability: 99%+, Accuracy consistency: ±20% variation, Maintenance calls: 70% reduction

Building Resilient RTLS Digital Twins

Success patterns from 100+ implementations

Success Pattern Recognition

- Start Small, Think Big

Pilot with single use case, build confidence, expand based on proven value - Invest in Foundation

Robust infrastructure, comprehensive integration, strong security framework - Focus on Adoption

User-centric design, comprehensive training, continuous support - Measure and Iterate

Clear baselines, regular ROI assessment, continuous optimization

Implementation Timeline

- Foundation (4–6 weeks) – Assessment, architecture design, stakeholder alignment

- Infrastructure (6–8 weeks) – Hardware deployment, network setup, initial integration

- Development (8–10 weeks) – Digital twin modeling, analytics, enterprise integration

- Pilot (4–6 weeks) – Limited deployment, user training, performance testing

- Rollout (8–12 weeks) – Full deployment, change management, optimization

- Optimization (Ongoing) – Performance monitoring, ROI measurement, scaling

Technical Excellence

- Robust architecture design and validation

- Comprehensive testing at each phase

- Performance monitoring and optimization

- Security and compliance adherence

Organizational Readiness

- Strong executive sponsorship

- Dedicated project team and resources

- Comprehensive change management

- Continuous stakeholder engagement

Operational Excellence

- Clear KPIs and success metrics

- Regular value assessment and reporting

- Continuous improvement processes

- Scaling and expansion planning

Key Takeaway

Every challenge in RTLS Digital Twin implementation represents an opportunity for competitive advantage. Organizations that successfully navigate these challenges don’t just implement technology—they transform their operations, culture, and competitive position. The key is approaching implementation with realistic expectations, comprehensive planning, and commitment to continuous improvement.

German Automotive OEM - Tool Management Excellence

Executive Summary

A major German automotive manufacturer operating one of Europe’s largest production facilities implemented RTLS Digital Twin technology to address critical tool management challenges across their 2-million-square-foot operation with 15,000+ specialized tools in circulation across 8 production lines.

Business Challenge

15,000+ specialized tools across 2M sq ft facility with critical tool loss and quality issues from uncalibrated tools affecting 200+ vehicles per shift production.

RTLS Solution

Ultra-Wideband (UWB) infrastructure with 10–30cm accuracy integrated with Manufacturing Execution System (MES) and digital twin platform for real-time visualization.

Key Results Achieved

38min → 2min

73% reduction

€1.2–1.8M

"The integration transformed our production floor from reactive to predictive operations with unprecedented tool accountability."

Implementation Timeline

14 months total (12-week pilot, 18-month phased expansion)

Technology Stack

- Ultra-Wideband (UWB) infrastructure providing 10–30cm accuracy

- Integration with existing Manufacturing Execution System (MES)

- Digital twin platform for real-time visualization

- Predictive analytics for tool maintenance scheduling

- Mobile applications for production workers

Implementation Approach

- 12-week pilot deployment in single production hall

- Comprehensive tool tagging and calibration baseline

- MES integration and workflow optimization

- Phased expansion across remaining 7 production lines

- Integration with quality management systems

- Mobile application rollout and worker training

Implementation Challenges & Solutions

RF interference in metal-heavy manufacturing environment affecting signal accuracy

Solution:Deployed mesh networking with redundant anchor points and advanced signal processing algorithms

Integration complexity with legacy MES systems and multiple production line configurations

Solution:API-first architecture with custom middleware for seamless data flow and real-time synchronization

Worker adoption and change management across multiple shifts and languages

Solution:Comprehensive training program with multilingual mobile interfaces and champion user network

Operational Improvements

- Tool Search Time 95% reduction

From average 38 minutes to under 2 minutes per search incident - Production Line Stoppages 73% reduction

Dramatic decrease in production delays due to missing tools - Tool Inventory Requirements 22% reduction

Better utilization eliminated need for excess tool inventory - Quality Incidents Near-zero

Eliminated quality issues from uncalibrated tools

Financial Impact

- Payback Period 14 months

Based on ARC Advisory Group automotive benchmarks - Annual Savings €1.2–1.8M

Combination of productivity gains and inventory optimization - Productivity Improvement 12–18%

Overall production efficiency gains across all lines

Key Lessons Learned

- Phased deployment approach critical for managing complexity and ensuring adoption

- Integration with existing MES systems provides exponential value beyond standalone RTLS

- Mobile worker interfaces essential for real-time feedback and system effectiveness

- Predictive maintenance capabilities emerged as unexpected high-value use case

- Quality system integration provides compliance benefits beyond operational efficiency

Industry Applicability

This implementation demonstrates proven patterns that can be adapted across similar manufacturing environments and related industries.

Transferable Success Factors:

- Phased implementation approach

- Strong executive sponsorship

- Integration-first architecture

- Continuous improvement methodology

Critical Considerations:

- Change management investment

- Infrastructure readiness assessment